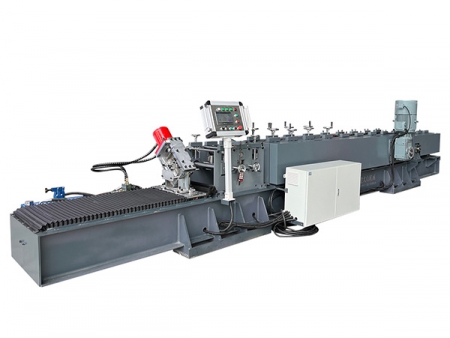

Solar Panel Mount Roll Forming Machine

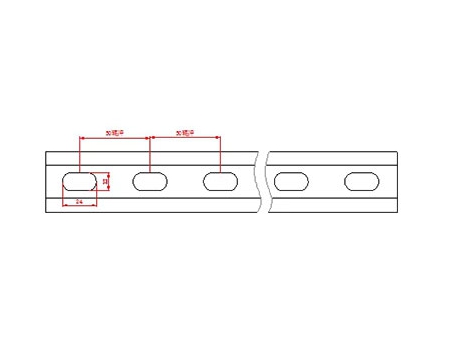

The solar panel mount roll forming machine is an integrated production line designed specifically for manufacturing channel profiles with slotted holes in various sizes, making it ideal for solar photovoltaic system racks. These reusable metal profiles are commonly used for pipe supports, cable tray brackets, duct supports, and solar panel mounting frames, offering a versatile solution across multiple industries.

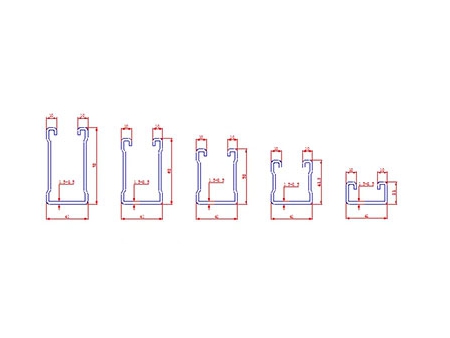

Available sizes for 41-21, 41-41, 41-52, 41-62, 41-72 five profile types which are formed with continuous rotary punching.

Specifications| Feeding Material | Raw Material | Q235/ Q345 |

| Material Thickness | 1.5-2.5mm | |

| Material Width | Approx. 98mm-200mm | |

| Uncoiler | Main Motor Power | 3kW |

| Coil Width | 350mm | |

| Inner Diameter | 450-530mm | |

| Max. Loading | 4T*2 rolls | |

| XHH300 Rotary Punching Machine | Main Motor Power | 15kW |

| Lifting Motor Power | 3*0.37kW | |

| Rotary Punching Speed | 0-50m/min | |

| Material Thickness | 1.5-2.5mm | |

| Rotary Punching Width | 98-200mm | |

| ZD/C21-72 Solar Panel Mount Roll Forming Machine | Main Motor Power | 2*22kW |

| Motor for Machine Size Control | 2*0.75kW | |

| Forming Speed | 0-50m/min | |

| Feeding Width | 98-200mm | |

| Roll Thickness | 1.5-2.5 mm | |

| Forming Steps | 24steps | |

| Rollers | Cr12Mov steel with heat treatment, hard chrome plating | |

| Shaft | 40Cr steel | |

| Continuous Cutting Device | Cutting Method | Post cutting (no scrap generated) |

| One blade set for each size: 21x41 / 41x41 / 52x41 / 62x41 / 72x41 | ||

| Cutter Material | Cr12Mov | |

| Tracking Motor Power | 3kW (servo motor) | |

| Hydraulic Station | Hydraulic Motor Power | 4kW |

| Parts Brand | YUKEN | |

| Fuel Tank Volume | 80L | |

| Control System | Brand | Delta |

| Cutting tolerance | ±2 mm | |

The entire equipment setup is customized according to the specific requirements of the client. Potential components may include a decoiler, leveling unit, punching system, roll forming section, cutting unit, material rack, and more.