Coffee Capsule Filling and Sealing Machine

Powder filling machine for packaging coffee pods and capsules

Designed to meet the high standards of specialty coffee packaging, this coffee capsule filling and sealing machine is a suitable choice for ensuring that each coffee pod and capsule maintains freshness and extended shelf life. Its simple design optimizes workspace utilization while reducing labor costs, making it an essential addition to any coffee production line seeking efficiency and precision.

| Material of Machine Parts | All parts in contact with product are made from food grade stainless steel AISI 304 |

| Certification | CE, SGS, ISO 9001, FDA, CSA, UL |

| Product | Fresh ground coffee; instant coffee; tea products; other food powder |

| Capacity | 45-50 pieces/per minute |

| Coffee Feeding | Auger filler driven by servo motor |

| Filling Accuracy | ±0.15g |

| Filling Range | 0-20 g |

| Sealing | Pre-cut lid sealing |

| Hopper Capacity | 5L (around 3kg powder) |

| Power | 220V, 50Hz, 1Ph, 1.5kW |

| Compressed Air Consumption | ≥300 L/minute |

| Compressed Air Supply | Dry compressed air, ≥6 Bar |

| Nitrogen Consumption | ≥200 L/minute |

| Weight | 800Kg |

| Dimension | 1900mm(L)×1118mm(W)×2524mm(H) |

| Note: Compressed air and nitrogen are prepared by customer. | |

Vertical Capsules/Cups Loading

- Shelves are provided for auxiliary storage, enhancing the filling and sealing machine's capacity by holding additional capsules and cups

- A storage bin accommodates 150-200 capsules or cups, ensuring a steady supply for uninterrupted operation

- The stable separation system guarantees reliable and precise handling, separating capsules and cups efficiently. The vacuum holding device at the bottom securely grips each capsule or cup, aiding in accurate and stable processing during filling.

Empty Capsule Detection Mechanism

This filling machine uses light sensor technology to identify empty capsules in the mold plate holes. This ensures that filling and other processes are only initiated when capsules are ready, enhancing the efficiency and accuracy of the packaging process.

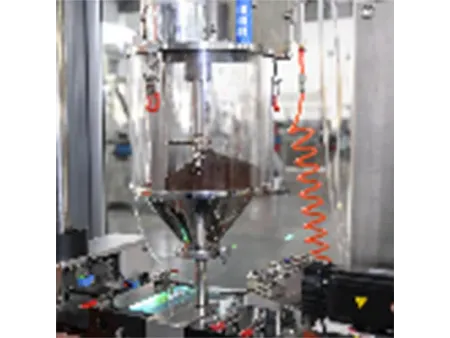

Filling System Specifications

- Precision in filling is achieved through an auger filler driven by a servo motor, ensuring consistent dosage and uniformity in every capsule

- The constant speed mixing device maintains the coffee's density uniformly, preventing cavities and ensuring consistent quality and flavor

- Operators can easily monitor coffee levels thanks to the visualized hopper, which also facilitates quick refills and reduces downtime

- Cleaning and maintenance are simplified as the entire hopper is designed to be pulled out and moved, promoting operational efficiency

- A special filling outlet structure stabilizes weight measurements and reduces powder spreading, keeping the workspace clean and ensuring product consistency Powder level detection and the vacuum feeder automate powder conveyance based on current levels, maintaining optimal filling without manual adjustments

Capsule/Cups Top Edge Clean-Up and Tamping Process

- A powerful vacuum clean-up device effectively cleans the top edge of capsules and cups, ensuring a good sealing effect and maintaining packaging quality.

- Adjustable pressure stamping compacts the coffee powder firmly, enhancing the espresso's quality by ensuring a richer crema and more flavorful extraction.

Precut Lids Stack Magazine Operation

- Features a vacuum sucker that efficiently picks lids from the stack, placing them accurately on top of the capsules. It can hold up to 2000 precut lids, minimizing the need for frequent refills.

- Lids are dispensed and placed one by one on the capsule's top, ensuring precise placement and consistently high quality in the final product appearance.

Heat Sealing Station

Once the lid is placed on the capsule's top, a lid sensor checks its presence. If the lid is detected, the filling and sealing system proceeds to heat-seal it onto the capsule. Both the sealing temperature and pressure are adjustable, ensuring a perfect seal every time, preserving freshness and preventing leaks.

Finished Capsules/Cups Discharging Process

- The packaging machine features a stable and orderly grab system that ensures capsules and cups are handled gently but firmly.

- A precise rotation and placement system positions each capsule accurately for further processing or packaging. As an optional feature, the coffee and tea packaging machine can pick and place finished capsules onto a 1.8-meter conveyor belt, streamlining the collection process for further handling or packaging.

Vacuum Feeding Machine

- This coffee and tea packaging machine automatically transfers powder from a tank to a 3kg capacity auger hopper via a pipe system. The vacuum feeding machine will cease operation when the hopper is full of powder and resume automatically if the level decreases, maintaining efficiency

- The system maintains a permanent nitrogen level inside, preventing oxidation and preserving the quality and flavor of the powder throughout the process

Reject Sub-quality Products

- The tea and coffee packing machine efficiently identifies and ejects any capsules that are missing powder or have failed to seal properly. These rejected capsules drop off the conveyor and are collected in a scrap box, where they can be recycled and reused.

- Additionally, integrating an optional check weigher function allows the packaging machine to detect and reject capsules based on incorrect weight. These too are directed into the scrap box, ensuring that only products meeting the quality standards proceed in the production process.

Nitrogen Input System and Protection Device

- This packaging system uses clear organic glass to encase the mold, ensuring the entire process, from the empty capsule feeding station to the sealing lids station, is conducted in a nitrogen-enriched environment. This approach prevents oxygen from affecting the coffee's quality.

- The powder hopper is also equipped with a nitrogen inlet to maintain this protective atmosphere throughout the coffee production process. By keeping the environment filled with nitrogen, the system ensures that the oxygen content in each capsule is reduced to below 2%.

- This significant reduction in oxygen preserves the coffee's aroma and extends its shelf life by preventing oxidation.