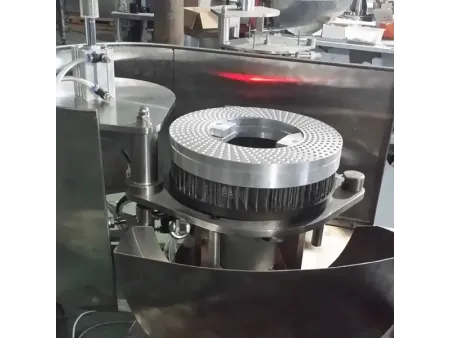

Semi-Auto Capsule Filling Machine

Capsule filler for filling hard capsules with powder and granules

The Semi-Auto Capsule Filling Machine offers a significant upgrade over traditional models. for filling hard capsules with powders and granules, this machine is the result of extensive research and development, enhancing upon older models for greater efficiency and user-friendliness. It is ideally suited for small to medium-sized pharmaceutical companies, research institutions, and hospital pharmacies looking to increase production capabilities while reducing labor intensity. It features an innovative capsule dropping, U-turning, and vacuum separation system that outperforms older models, making the operation more intuitive and efficient.

The newly designed capsule orientating system utilizes a columnar pill positioning mechanism, reducing mold replacement time from 30 minutes to just 5-8 minutes. It is equipped with electricity and pneumatic combined controls, automatic counting electronics, a programmable controller, and a frequency conversion speed regulator to maximize production accuracy and consistency. By automating processes that were previously manual, this machine significantly reduces labor intensity, making capsule production more manageable. Compatible with both domestically produced and imported capsules, achieving a finished product qualification rate of over 98%, ensuring high standards of quality and performance.

| Model | ||

| Capacity | 15000-28000pcs/h (with single set of mould) | 15000-28000pcs/h (with single set of mould) |

| Applicable Capsules | 000#/00#/0#/1#/2#/3#/4#/5# | 000#/00#/0#/1#/2#/3#/4#/5# |

| machine-made standard capsules | machine-made standard capsules | |

| Filling Materials | Powder or small granules (can not be wet and sticky) | Powder or small granules (can not be wet and sticky) |

| Air Pressure | 0.03m3/min,0.7Mpa | 0.03m3/min,0.7Mpa |

| Vacuum Pump | 40m3/h | 40m3/h |

| Total Power | 2.12kW, 380V, 50Hz, 3Phs | 2.12kW, 380V, 50Hz, 3Phs |

| Overall Dimensions (L×W×H) | 1300×800×1750mm | 1300×800×1750mm |

| Weight | 400kg | 400kg |

Includes mechanisms for capsule-feeding, U-turning, separating, material filling, and locking, along with a speed varying and adjusting mechanism, and comprehensive electrical and pneumatic control system protection. It also comes equipped with essential accessories like a vacuum pump and air pump.