Tea Bag Packaging Machine (Inner and Outer Bag)

Request a Quote

LQ-NT-2

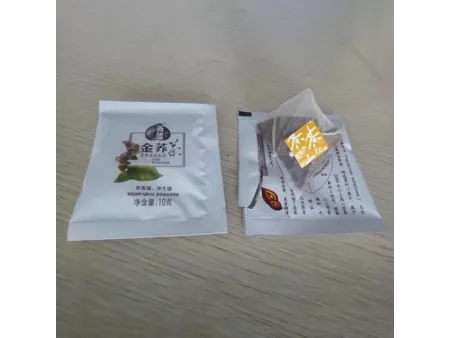

Tea packaging machine for packing tea leaves with both inner bag and outer envelope

Our tea bag packaging equipment is designed to pack tea leaves first into an inner bag and then into an outer envelope. This tea packaging system efficiently handles flat and pyramid tea bags, catering to various tea types and ensuring each bag is perfectly sealed and presented.

Main Components

- Sealing Part

- Cabinet

- Electronic Weighing System

- Waste Film Collector

Specifications

| Working Speed | Approximately 50 bags/min |

| Inner Bag Film | 120mm, 140mm, 160mm, 180mm |

| Bag Type | Pyramid bag or flat bag |

| Sealing Method | Inner bag: ultrasonic sealing |

| Outer bag: heat sealing | |

| Outer Bag Size | Length: 80-140mm Width: 70-120mm |

| Weight Range | 0.5-20g |

| Filling Accuracy | ±0.2 grams/bag (depending on coffee material) |

| Weighing System | Weigher |

| Max. 6 heads weigher | |

| Compressed Air | 0.6MPa, 200L/min |

| Power Supply | 220V, 50Hz, 1Ph, 2kW |

| Weight | 650kg |

| Overall Dimensions | 3663mm×1040mm×2015mm |

Features

- Easily switch between flat and triangular packaging bags with a single button

- Capable of packing up to 3000 bags per hour, depending on the material

- Compatible with packing film that includes a string and a tag, ensuring convenient use for consumers.

- Electronic weighing system tailored to the characteristics of the materials, suitable for single, multi-materials, and irregular-shaped materials. Each system can be independently controlled

- High-precision turntable metering mode significantly improves production efficiency

- Automatic tension adjusting device for packaging material

- Equipped with a touch screen, PLC, and servo motor for comprehensive setting functions, allowing maximum operational flexibility

- Features automatic fault alarm and automatic shutdown

- Automates the entire process including cutting, measuring, bag making, sealing, counting, and finished product conveying

- Precise control system ensures accurate adjustments, with a compact structure and user-friendly interface for easy operation and maintenance

- Servo motor-driven bag length control ensures stable, accurate positioning and easy adjustments

- Inner bag uses ultrasonic sealing and cutting technology for firm and reliable sealing and cutting

- Independent switching between inner and outer bags, allowing them to work linked or separately