Agitator Tank Recycling System

The agitator tank recycling system is widely used by concrete producers that lack fresh water resources and produce low strength concrete mixtures.

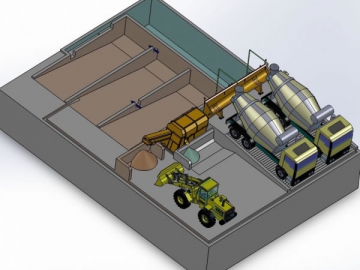

The recycling system operates in a closed loop system that is made up of a concrete reclaimer and a water filtration system. This equipment allows for waste concrete and the water used to clean the mixer truck to be reused in the batching plant. This enables a zero waste operation.

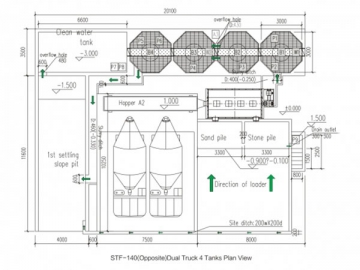

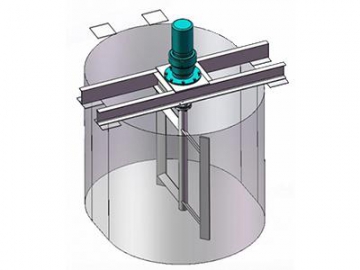

The standard design of the agitator slurry recycling system has 4 mixing tanks, 1 settling slope tank and 1 clean water tank.

The slurry pumps for the batching plant are placed in mixing tank 1, the slurry pumps for truck mixers and adding water are placed in mixing tank 3.

Working Principle

1. The mixing truck is parked in a designated position and the machine, once activated will fill the mixing chamber with water.

2. The waste concrete will be dumped into the hopper, then through the concrete reclaimer, effectively separating sand and stones.

3. The slurry water overflows to mixing tanks (2-4), where agitators prevent settling. Through the water sensors and pumps, the slurry water can be reused in the batching plant to replace a percentage of clean water to make new concrete, of which the waste can be 100% recycled.

| NO | Name | Model | Remarks |

| A1 | Concrete reclaimer | STF-140(opposite)/7.5kw | |

| A2 | Hopper | 7m (opposite) | |

| A3 | Electric control cabinet | PLC Automation | |

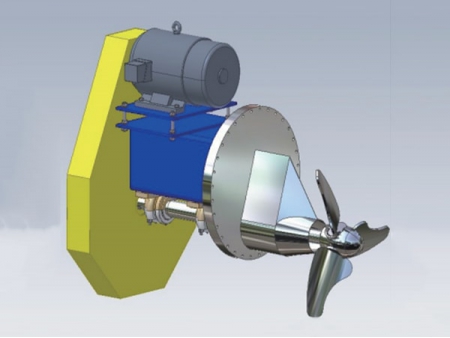

| B1-4 | Agitators | BLD-23-DXJ55-ZJ1300/5.5kw | |

| W1-3 | Water level controller | Electrode type | |

| P1-2 | Batching pump | 80SWQ65-25-7.5 | Pump slurry to batching plant |

| P3 | Hopper pump | 50WQ20-25-3kw | Pump slurry to wash hopper |

| P4 | Slurry add pump | WQ 15-20-2.2 | Add slurry to tankl ,2# |

| P5-6 | Truck pump | 50WQ20-25-3kw | Pump water to wash mixer trucks |

| P7-8 | Water add pump | WQ 15-20-2.2 | Add water to tank3,4#,wash reclain |

| P9 | Drain pump | 50WQ10-10-0.75 | Drain out water |

Other search items: agitation tank