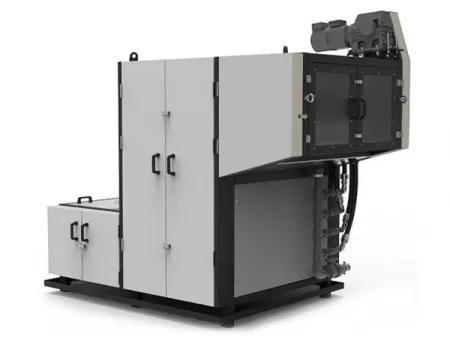

Filter Press System

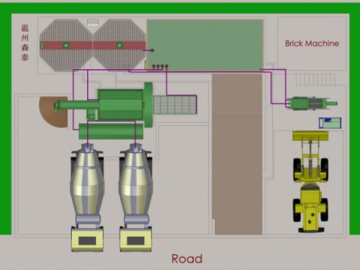

The filter press system is employed by large concrete producers that need to recycle clean water as well as concrete waste. These systems allow these operations to produce dry cakes and usable clean water, realizing a zero waste and zero discharge process.

Working Principle

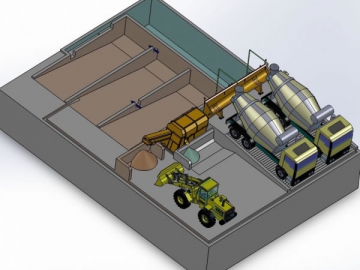

1. The mixing truck is parked in the designated spot and the system is activated, filling the mixing chamber with water.

2. Waste concrete is dumped in the hopper and then passes through the concrete reclaimer, separating sand and stones.

3. The slurry water overflows into 2 mixing tanks with agitators to prevent settling. Through the water sensors and pumps, the slurry water is pumped into the filter press, and through the filter press system, cleaning the water and forming recyclable cakes of waste.

4. The clean water can then be reused in the batching plant or for washing truck mixers. The remaining water can be discharged after the PH control system. The sludge cakes can be reused to produce bricks and blocks.

Advantages

PLC Automatic Control

Flap board to prevent water from drop ping onto the muddy cakes.

Through the electric slurry valve, the discharge of slurry water can be separated from the clean water.

| Filter Press Technical Parameters | |||

| 1 | Model | ||

| 2 | Filtration Area(M2) | 35 | 15 |

| 3 | No. of Plates(PCS) | 19 | 13 |

| 4 | Cake Thickness(mm) | 30 | 30 |

| 5 | Chamber Volume(L) | 518 | 230 |

| 6 | Plate Size(mm) | 1000*1000 | 870*870 |

| 7 | Plate Material | RFPP | RFPP |

| 8 | Max. Hydraulic Pressure(MPa) | 20 | 20 |

| 9 | Filtration Pressure(MPa) | 0.6 | 0.6 |

| 10 | Press Type | Hydraulic press, mechanical pressure | Hydraulic press, mechanical pressure |

| 11 | Hydraulic Station Power(KW) | 4 2.2 | 4 0.75 |

| 12 | Weight(Kg) | 4100 | 1500 |

| 13 | Out size(mm) | 3400*1450*1560 | 2750*1300*1600 |

| 14 | Moisture Content (%) | 60--70 | 60--70 |

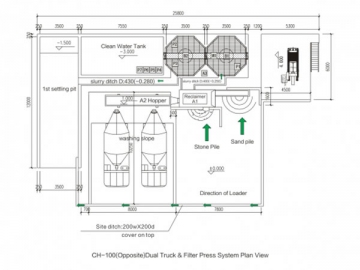

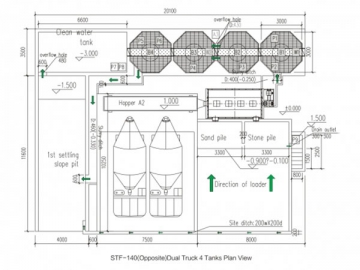

| NO | Name | Model | Remarks |

| A1 | Concrete reclaimer | CH100 (opposite) /8kw | |

| A2 | Hopper | 7m (opposite) | |

| A3 | Electric control cabinet | PLC Automation | |

| B1-2 | Agitators | BLD13-23-DXJ55-ZJ1300/5.5kw | |

| W1 | Water level controller | Electrode type | |

| P1 | Press filling pump | 65wq40-50-11kw | Pump slurry to filter press |

| P2 | Hopper pump | 50WQ20-25-3kw | Pump slurry water to hopper |

| P3 | Slurry add pump | WQ 15-20-2.2 | Add water to tank 1 #,2# |

| P4-5 | Truck mixer pump | 50WQ20-25-3kw | Wash truck mixers |

| P6 | Reclaimer pump | WQ 15-20-2.2 | Wash concrete crete reclaimer |