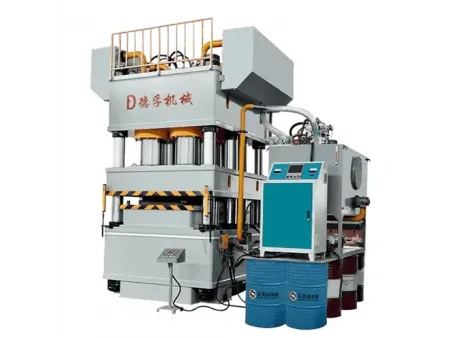

Double-Action 8-Column Hydraulic Embossing Press

YDM32 Hydraulic Presses

- Nominal capacity 20000kN to 36000kN

- Return capacity 380kN to 760kN

- Slide stroke 500mm

- Table size (L-R×F-B) 1480×2500mm to1500×2700mm

The YDM32 double-action 8-column hydraulic embossing press is specially designed for high-efficiency metal embossing applications such as steel doors, leather textures, and stainless steel panels. This press offers stable performance and customizable specifications for table size, stroke, and tonnage, making it adaptable to various production needs.

With a nominal capacity ranging from 20,000kN to 36,000kN and a 500mm slide stroke, the embossing press supports powerful, consistent forming. Built with either a three-beam eight-column six-cylinder structure or frame-type structure, it ensures excellent guiding performance and precision retention.

The machine features an independent hydraulic and electrical system with centralized button control, allowing for adjustment, manual, and semi-automatic operation modes. Operators can adjust working pressure, pressing speed, and stroke ranges to meet specific process requirements for both pressure-based and stroke-based forming.

High-quality Schneider electric components are used for safe and reliable control, with clear circuit layouts and a complete electrical schematic provided upon delivery. Optional configurations include light curtain protection, cooling systems, and PLC control. The machine also integrates advanced processing techniques such as shot-blasted oil tanks, high-pressure dust removal, and residue clearance.

- Metal embossing

- Leather embossing

- Stainless steel embossing

- Three-beam eight-column structure ensures excellent stability and load balance

- Welded and stress-relieved frame construction for long-term precision

- Integrated valve hydraulic system with long service life and minimized hydraulic shock

- Pre-release system in hydraulic circuit to reduce pressure impact

- Centralized button control with adjustment and semi-automatic modes

- PLC-controlled system for efficient, safe, and intuitive operation

- Customizable components available, including Mitsubishi, Siemens, Bosch Rexroth, Schneider, and DELIXI

| Model | Unit | |||||

| Nominal capacity | kN | 36000 | 30000 | 24000 | 20000 | |

| Return capacity | kN | 760 | 500 | 380 | 380 | |

| Max. working pressure | MPa | 25 | 25 | 25 | 25 | |

| Slide stroke | mm | 500 | 500 | 500 | 500 | |

| Max. opening height (daylight) | mm | 600 | 600 | 600 | 600 | |

| Slide speed | Descent | mm/s | 120-150 | 120-150 | 120-150 | 120-150 |

| Pressing | mm/s | 8-12 | 8-12 | 8-12 | 8-12 | |

| Return | mm/s | 120 | 120 | 120 | 120 | |

| Table size | Left-Right | mm | 1500 | 1500 | 1500 | 1480 |

| Front-Back | mm | 2700 | 2600 | 2500 | 2500 | |

| Ejector pressure | kN | 16000 | 15000 | 12000 | 8000 | |

| Main motor power | kW | 74 | 60 | 52 | 44 | |

Note: The above models represent our standard configurations. Custom designs and special specifications can be developed according to your specific requirements.

Our product brochure

The double-action 8-column hydraulic embossing press provides powerful, stable, and intelligent performance for high-precision metal forming. Contact us to customize a solution tailored to your production line.