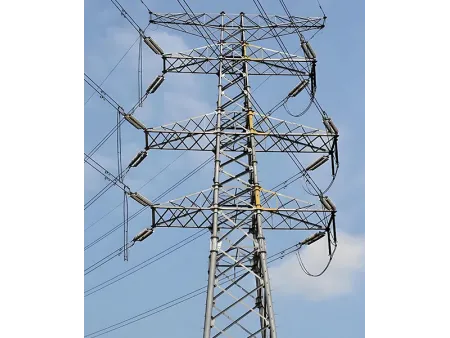

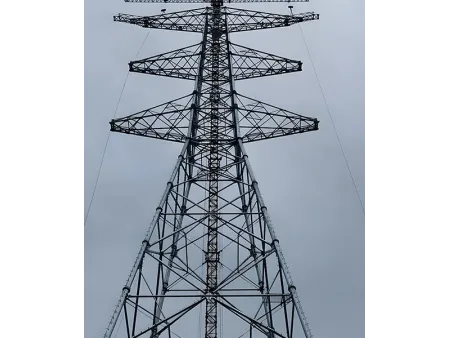

Tubular Steel Power Transmission Tower

Self-supporting lattice tower constructed from tubular steel members for power transmission lines, available in height options from 5 to 60 meters

Tubular steel power transmission towers are key support structures used across power transmission systems. Compared with angular steel towers, they offer stronger performance under heavy loads and are often selected for long-span or high-demand transmission corridors.

- Design Standard ANSI/TIA-222-G/H/F; EN 1991-1-4; EN 1993-3-1

- Height Range 5–60 m, as per customer’s requirement

- Design Wind Speed 0–300 km/h, adjusted according to regional conditions

- Surface Treatment Hot-dip galvanized

- Main Materials

The energy transmission line tower is built with tubular steel members. Bracing components are made from tubular steel, round steel bars, or structural steel sections to form a stable space-frame structure. - Connection Technology

Main members are connected using flanges, including stiffened or necked flange designs. Bracing components use insert-plate connections. These joints provide greater rigidity than the bolted connections typically used in angular steel towers. - Load Capacity

Tubular towers are suitable for long-span and heavy-load conditions, such as crossings over rivers or valleys. In extra-high-voltage projects, tubular steel towers account for approximately 18% of all tower types. - Wind and Seismic Performance

The circular cross-section reduces wind pressure to about half that of angular steel members. This lowers overall wind load on the tower by 40–50% and significantly improves seismic performance. - Economic Efficiency

With the same cross-sectional area, tubular steel members provide a larger radius of gyration and better compression–bending stability. This can reduce material usage while maintaining structural strength.

Typical Installation Environments

Tubular steel power transmission towers should be installed with local climate and terrain conditions in mind. Proper site selection ensures long-term structural stability and reliable performance.

- Plains

Projects in plains should focus on high-wind conditions. The tower must provide adequate wind resistance to ensure stable operation during strong weather events. - Mountain Areas

Mountain sites have complex terrain and varied wind patterns. The tower should be designed with enhanced structural strength, higher wind-load resistance, and additional lightning protection. - Coastal Rregions

Coastal projects face typhoons, salt spray, and corrosive environments. Materials with strong corrosion resistance are essential to maintain tower performance over time. - Geologically Sensitive Zones

Sites with weak geology such as landslide-prone or debris-flow areas should be avoided. Solid ground with high bearing capacity is preferred for safe and reliable foundation construction.

| Product | Power transmission tower |

| Safety factor | Safety factor for conductors: 2.5-4.0; Safety factor for grounding: 2.5-4.0 |

| Ultimate Tensile Strength | 490 kPa – 620 kPa |

| Min. Yield Strength | 355 kPa |

| Manufacturing Standard | DL/T 646-2012, DL/T 5214-2014, DL/T 5220-2021 |

| Quality Certification | ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV) |

| Nuts & Bolts | Grade 8.8 / 6.8 / 4.8; A325; DIN 7990, DIN 931, DIN 933; ISO 4032, ISO 4034 |

| Main Material | Q355B tube steel |

| Height Range | 5–60 m, as per customer's requirement |

| Design Wind Speed | 0–300 km/h, adjusted according to regional conditions |

| Surface Treatment | Hot-dip galvanized |

| Galvanizing Standard | ASTM A123; ISO 1461 |

| Expected Service Life | More than 20 years |

| Color Options | Silver (galvanized) or painted finish, RAL color system, customizable |

| Seismic Resistance | Up to 8° seismic intensity |

| Appropriate Temperature | −60° to 60° |

| Rated Voltage | 10 kV, 33 kV, 66 kV, 110 kV, 132 kV, 220 kV, 380 kV, 400 kV, 500 kV, 750 kV, 1000 kV |

| Welding | Welding complies with AWS D1.1. CO₂ welding or submerged-arc automatic welding ensures no fissures, overlap, or defects. Internal and external welds provide a smooth, uniform finish. Adjustments can be made according to customer requirements. |

| Base Plate | Square, round, or polygonal base plates with slotted holes for anchor bolts; dimensions customizable per client requirements |

| Certification Standard | ||

| Design Standards |

| |

| Structural Steel | ||

| Grade | Mild Steel | High Tensile Steel |

| GB/T 700 – Q235B, Q235C, Q235D | GB/T 1591 – Q355B, Q355C, Q355D, Q420B | |

| ASTM A36 | ASTM A572 Gr.50 | |

| EN 10025 – S235JR, S235J0, S235J2 | EN 10025 – S355JR, S355J0, S355J2 | |

| Design Wind Speed | Up to 300 km/h | |

| Allowable deflection | 0.5–1.0° @ operational speed | |

| Tensile strength (MPa) | 360–510 | 470–630 |

| Yield strength (t ≤ 16 mm) (MPa) | 235 | 355 / 420 |

| Elongation (%) | 20 | 24 |

| Impact strength KV (J) | 27 (20°C) - Q235B (S235JR) | 27 (20°C) - Q355B (S355JR) |

| 27 (0°C) - Q235C (S235J0) | 27 (0°C) - Q355C (S355J0) | |

| 27 (-20°C) - Q235D (S235J2) | 27 (-20°C) - Q355D (S355J2) | |

| Bolts & Nuts | ||

| Grade | Grade 4.8, 6.8, 8.8 | |

| Standards for mechanical properties | ||

| Bolts | ISO 898-1 | |

| Nuts | ISO 898-2 | |

| Washers | ISO 7089 / DIN 125 / DIN 9021 | |

| Standards for dimensions | ||

| Bolts (dimensions) | DIN 7990, DIN 931, DIN 933 | |

| Nuts (dimensions) | ISO 4032, ISO 4034 | |

| Washers (dimensions) | DIN 7989, DIN 127B, ISO 7091 | |

| Welding | ||

| Method | CO₂ Shielded Arc Welding & Submerged Arc Welding (SAW) | |

| Standard | AWS D1.1 | |

| Galvanizing | ||

| Galvanization standard of steel sections | ISO 1461 or ASTM A123/A123M | |

| Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153/A153M | |

Main & Optional Components

- Anchor Bolts

- Copper Grounding Material

- Connection Plates

- Accessory Bolts

Tubular steel power transmission towers use steel tube sections as the main structural material. Most secondary components are also made from tubular or structural steel, forming a stable lattice-frame tower. These structures are widely used in transmission corridors to support and elevate conductors, ensuring safe and reliable power delivery.

Steel offers strong load-bearing capacity and good toughness. The tower can withstand conductor tension, self-weight, wind load, and seismic forces. This ensures stable performance across different terrains and climates, including mountain regions and coastal zones.

Most steel components can be prefabricated in the factory and transported to the site for assembly. This shortens the construction schedule and allows the tower to be installed quickly, helping projects enter service sooner.

Connections use bolting or welding, making it easier to replace damaged components and reducing long-term maintenance costs. Surface treatment such as hot-dip galvanizing improves corrosion resistance and extends service life.

The tower’s geometry can be adjusted to meet different environmental or visual requirements, helping it blend into varied surroundings. Steel materials are recyclable, supporting sustainable development goals.

Laser Cutting

Laser cutting is used to shape the steel components through focused beam cutting and assisted gas removal. The process offers fast cutting speed and high dimensional accuracy (up to ±0.05 mm), while keeping heat impact to a minimum. This reduces the risk of deformation and results in clean, well-defined edges.

CNC Punching and Shearing

Steel angles are processed through CNC-controlled punching and shearing lines. Automatic feeding, positioning, punching, and cutting are all integrated into the process, keeping production running smoothly and efficiently. Precise CNC positioning keeps quality consistent, even when working with more complex parts.

Hot-Dip Galvanizing and Surface Protection

The tower is protected with hot-dip galvanizing as the main anti-corrosion treatment, along with an extra plastic coating for added protection. The zinc layer protects the steel from rust and adds strength, while the coating gives extra insulation and surface protection. This combined treatment allows the tower to maintain reliable performance for over 20 years and adapt well to harsh environments such as high and low temperatures, coastal areas, and mountainous regions.