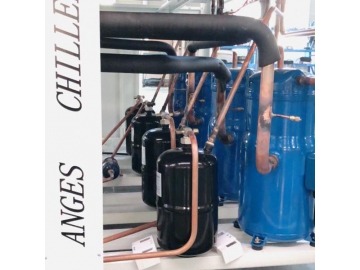

Water-cooled Scroll Chiller

- Cooling capacity: 10.4-204kW

- Compressor type: Scroll

- Flow Rate: 4~48 m³/h

Anges water-cooled scroll chiller was particularly designed to provide chilled water for central air conditioning system, it can be widely applied in medium and small-size offices, factories, restaurants and villas for cooling needs. Our water-cooled chiller can be configured with multiple compressors, providing improved energy efficiency in comparison with split air conditioner.

The water-cooled scroll chiller adopts shell & tube evaporator to ensure high efficiency, excellent energy saving and reliable stability, stainless steel plate evaporator is also configurable as per your request. A range of eco-friendly refrigerants is available, such as R22, R407C, R410A and R134A.

Cooling capacity: 15.8kW-161kW

Chilled water temperature: 5℃-30℃

Cooling capacity: 15.8kW

Total input power: 4.05kW

Compressor type: Scroll

Standard flow rate: 4m³/h

Evaporator: Shell and tube

Cooling capacity: 31.6kW

Total input power: 8.1kW

Compressor type: Scroll

Standard flow rate: 11.4m³/h

Evaporator: Shell and tube

Cooling capacity: 51kW

Total input power: 11.7kW

Compressor type: Scroll

Standard flow rate: 12.5m³/h

Evaporator: Shell and tube

Cooling capacity: 68kW

Total input power: 15.4kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 80.6kW

Total input power: 17.8kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 102kW

Total input power: 22.6kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 136kW

Total input power: 30.4kW

Compressor type: Scroll

Standard flow rate: 48m³/h

Evaporator: Shell and tube

Cooling capacity: 161.2kW

Total input power: 45.2kW

Compressor type: Scroll

Standard flow rate: 48m³/h

Evaporator: Shell and tube

| Model | Cooling capacity | Total input power | Compressor Type | Standard Flow Rate | Evaporator |

AWK-5 | 15.8kW | 4.05kW | Scroll | 4m³/h | Shell and tube |

AWK-10(D) | 31.6kW | 8.1kW | Scroll | 11.4m³/h | Shell and tube |

AWK-15 | 51kW | 11.7kW | Scroll | 12.5m³/h | Shell and tube |

AWK-20(D) | 68kW | 15.4kW | Scroll | 25m³/h | Shell and tube |

AWK-25(D) | 80.6kW | 17.8kW | Scroll | 25m³/h | Shell and tube |

AWK-30(D) | 102kW | 22.6kW | Scroll | 25m³/h | Shell and tube |

AWK-40(F) | 136kW | 30.4kW | Scroll | 48m³/h | Shell and tube |

AWK-50(F) | 161.2kW | 45.2kW | Scroll | 48m³/h | Shell and tube |

* Please download for details.

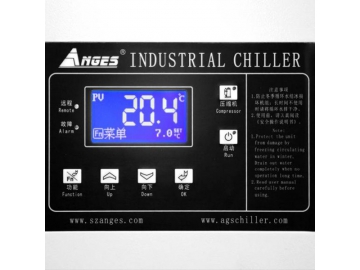

- Microcomputer control with user-friendly HMI interface, easy to operate; Siemens PLC control is optionally configurable as per customer's request;

- Adopting world's well-known compressors, such as Danfoss, Copeland and Panasonic, and our main electrical components are from Schneider;

- Built-in water pump and water tank (optional) can be easily installed and directly put into use by simply connecting water pipes and power supply;

- Designed with multiple protection functions, such as phase failure protection, flow protection, high/low pressure protection, overheat protection, providing high reliability, low failure rate and excellent performance;

- Stainless steel plate evaporator

- Common water pump or 4-8bar high pressure pump

- Water tank

- Low noise option

UV Printing and UV Curing

Water chillers are an ideal solution to control the temperature of UV LED lamp, efficiently maintaining the stability and durability of UV light source. Our industrial chillers are applicable to various UV printing and UV curing equipment, such as UV flatbed printing machine, UV screen printing machine, UV LED curing lamp, UV LED curing equipment, etc.

Rubber and Plastic

In rubber and plastic industry, precision temperature control is an essential factor for improving product quality and production efficiency. Injection molding is one of the most effective method to produce rubber and plastic parts. It requires heat to convert the plastic particles into molten status for injection into the mold where plastic parts cool down. The industrial chillers can perfectly reduce the cooling time and ensure the quality of plastic parts.