Automatic Stretch Hooding Machine

Stretch hooder system for wrapping pallets with stretch film

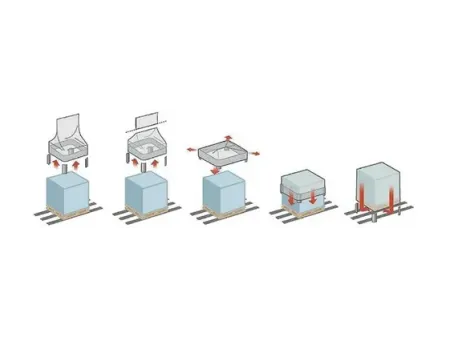

The stretch hooding process gently expands tubular stretch film and smoothly covers palletized goods from top to bottom, tightly securing items using the film’s natural elasticity. Unlike conventional stretch wrapping methods, stretch hooding cuts down film replacement intervals by as much as ten times and significantly enhances resistance to tearing and punctures. Besides securely holding pallet loads together, the hooding process provides effective protection against dust, moisture, and product spillage, keeping your packaged goods in pristine condition throughout transportation and storage.

Ideal for packaging various powdered materials, including dry-mix mortar, wall putty, self-leveling compounds, gypsum plaster, and similar construction products.

| Conveyor length at stretch hooding station | 1500mm 2000mm 1500mm |

| Film feeding speed | 170mm/s |

| Voltage | AC 380V, 3phase, 5 wire, 50Hz |

| Total power | Approx. 20kW |

| Pallet size | 1100×1300mm, 1000×1200mm, or customized |

| Pile height | 500-2250mm |

| Packaging speed | ≤60 pallets per hour |

Note: As we continuously improve our products through technological advancements, actual specifications and structural features may differ slightly from those listed. Please refer to the final design and actual product.

- Equipped with a film-stretching mechanism featuring position sensors, allowing continuous adjustment for precise film placement.

- Automatically detects pallet contours, ensuring customizable film lengths according to different load sizes.

- Its user-friendly visual interface simplifies parameter adjustments, offering intuitive operation and easy maintenance.