Pump & Motor Assemblies (Vane Pump/Motor Unit)

Request a Quote

Our pump & motor assemblies combine efficient vane pumps with high-performance motors, designed for industrial applications to provide excellent fluid transfer.

Features

- High efficiency & energy saving: Features a floating distribution plate design combined with a high-efficiency motor, significantly reducing energy consumption.

- Smooth operation: Dual-acting vane pump with radial hydraulic force balance technology reduces vibration and noise, extending equipment lifespan.

- Compact design: Integrated motor and pump body occupy minimal space, facilitating installation and maintenance, suitable for space-constrained environments.

- Durable & reliable: Constructed with high-strength composite materials and precision manufacturing processes, offering corrosion and wear resistance for demanding working conditions.

- Easy to maintain: Modular design allows for easy replacement of key components, reducing downtime and improving operational efficiency.

Applications

- Industrial manufacturing: Widely used in medium to low-pressure hydraulic systems for precision machine tools, injection molding machines, and pressing machinery.

- Construction machinery: Suitable for equipment like excavators and loaders, ensuring efficient hydraulic transmission.

Features

- Low energy consumption and high efficiency.

- Low noise and low temperature rise.

- Compact structure, lightweight, and miniaturized.

Applications

- Machine tools

- Automation equipment

- Rubber and plastic machinery

- Hydraulic cooling units

Technical Specifications

| General | Type: Three-phase Squirrel Cage Induction Motor (SCIM) |

| Voltage: Can be manufactured for voltages worldwide | |

| Frequency: Rated frequency 50HZ or 60HZ (50HZ/60HZ common specification available for 5HP and below) | |

| Output HP: 1~3HP | |

| Time rating: Continuous use within rated torque | |

| Cooling method: Totally Enclosed Fan Cooled (TEFC) | |

| Protection class: Totally Enclosed (IP54) | |

| Applicable Range | Power supply: Voltage fluctuation rate: within ±10%, Frequency fluctuation rate: within ±5% |

| Operating environment: General indoor environment, ambient temperature -10℃~40℃, humidity: below RH90% | |

| Drive method: Direct connection via single key shaft coupling drive | |

| Rotation: Forward rotation | |

| Characteristics | Test method: Based on International Electrotechnical Commission (IEC34), Chinese National Standard (CNS10919), tested with full voltage startup |

| Temperature rise: Stator winding temperature rise: below 75℃ by resistance method, Service Factor (S.F.) 1.0 | |

| Over-speed characteristic: 4P for 125% synchronous speed for 1 minute, 6P for 150% synchronous speed for 1 minute | |

| Over-torque characteristic: 160% rated torque for 20 seconds |

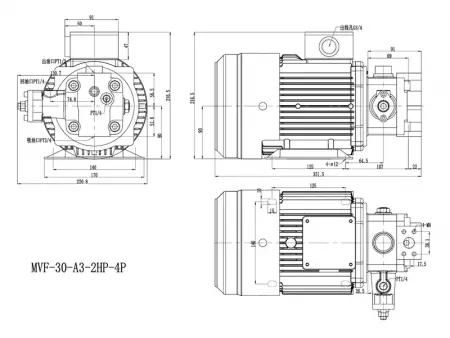

Dimensions (unit: mm)

- MVF-30-A3-2HP-4P

- MVF-30-A3-3HP-4P

- MVF-40-A3-3HP-4P

This unit offers stable quality and long-lasting durability. The motors are designed for full load operation above standard values, and the shaft steel is heat-treated for high pressure resistance and extended wear life. Custom specifications can be manufactured according to customer requirements.

Applications

- Machine tools

- Automation equipment

- Rubber and plastic machinery

- Hydraulic cooling units

Technical Specifications

| General | Type: Three-phase Squirrel Cage Induction Motor (SCIM) |

| Voltage: Can be manufactured for voltages worldwide | |

| Frequency: Rated frequency 50HZ or 60HZ (50HZ/60HZ common specification available for 5HP and below) | |

| Output HP: 1/2~10HP Frame size: 71-132 | |

| Time rating: Continuous use within rated torque | |

| Cooling method: Totally Enclosed Fan Cooled (TEFC) | |

| Protection class: Totally Enclosed (IP54) | |

| Applicable Range | Power supply: Voltage fluctuation rate: within ±10%, Frequency fluctuation rate: within ±5% |

| Operating environment: General indoor environment, ambient temperature -10℃~40℃, humidity: below RH90% | |

| Drive method: Direct connection via single key shaft coupling drive | |

| Rotation: Forward rotation | |

| Characteristics | Test method: Based on International Electrotechnical Commission (IEC34), Chinese National Standard (CNS10919), tested with full voltage startup |

| Temperature rise: Stator winding temperature rise: below 75℃ by resistance method, Service Factor (S.F.) 1.0 | |

| Over-speed characteristic: 4P for 125% synchronous speed for 1 minute, 6P for 150% synchronous speed for 1 minute | |

| Over-torque characteristic: 160% rated torque for 20 seconds |

Dimensions (unit: mm)

| A | AA | AD | B | C | D | H | h | L | |

| | 125 | 158 | 136 | 100 | 76.3 | 69.5 | 80 | 216 | 337 |

| | 125 | 158 | 136 | 100 | 78.7 | 95.5 | 80 | 227 | 365 |

| | 125 | 158 | 136 | 100 | 76.3 | 69.5 | 80 | 216 | 410 |

| | 140 | 177 | 145 | 125 | 73.5 | 69.5 | 90 | 226 | 364 |

| | 140 | 177 | 145 | 125 | 75.4 | 95.5 | 90 | 237 | 392 |

| | 140 | 177 | 145 | 125 | 75.4 | 95.5 | 90 | 237.4 | 476 |

| | 140 | 177 | 145 | 125 | 104 | 104 | 90 | 188 | 430 |

| | 160 | 200 | 157 | 140 | 88.4 | 95.5 | 100 | 247 | 427.4 |

| | 160 | 200 | 157 | 140 | 88.4 | 95.4 | 100 | 247 | 511.4 |