Eccentric Casing System

Maxdrill’s eccentric casing system is designed to effectively transmit the percussive force produced by DTH drilling tools into the rock and thus drills a hole in fissure or complex formations. A casing tube in the system helps prevent borehole collapse. The eccentric casing system features high drilling efficiency, quality holes, easy operation and low requirements of accessories. Choose Maxdrill’s eccentric casing system and you will handle complex formations drilling easily.

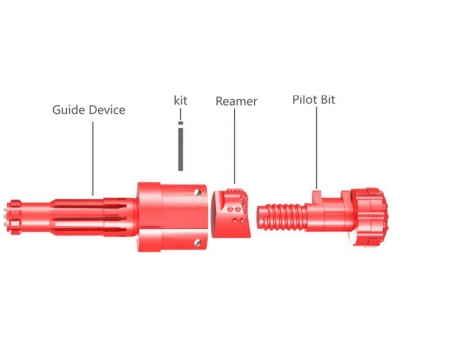

Three Piece Eccentric Overburden Drilling System

Maxdrill’s eccentric casing system is designed to effectively transmit the percussive force produced by DTH drilling tools into the rock and thus drills a hole in fissure or complex formations. A casing tube in the system helps prevent borehole collapse. The eccentric casing system features high drilling efficiency, quality holes, easy operation and low requirements of accessories. Choose Maxdrill’s eccentric casing system and you will handle complex formations drilling easily.

| Model | O.D of Casing Tube(mm) | I.D of Casing Tube (mm) | Wall Thickness of Casing Tube (mm) | Guide device max .Dia. (mm) | Reamed Dia.(mm) | Min I.D of Casing Shoe(mm) | O.D of Normal bit (mm) | Hammer Type | Weight (kg) |

| MDEC108/7 | 108 | 94 | 7 | 92 | 117 | 86 | 85 | COP34/DHD3.5 | 11.6/12.2 |

| MDEC114/6.5 | 114 | 101 | 6.5 | 99 | 125 | 92 | 90 | COP34/DHD3.5 | 13.4/14 |

| MDEC127/9 | 127 | 109 | 9 | 107 | 138 | 100 | 98 | COP34/DHD3.5 | 15.2/15.9 |

| MDEC146/10 | 146 | 126 | 10 | 123.5 | 155 | 117 | 115 | COP44/DHD340 /SD4/QL40 | 25/27.9 |

| MDEC168/10 | 168 | 148 | 10 | 146 | 180 | 138 | 136 | COP54/DHD350 /SD5/QL50 | 38/42 |

| MDEC178/10 | 178 | 158 | 10 | 156 | 192 | 147 | 145 | COP54/DHD350 /SD5/QL50 | 44.1 |

| MDEC183/10 | 183 | 163 | 10 | 161 | 196 | 153 | 151 | COP64/DHD360 /SD6/QL60 | 56 |

| MDEC194/10 | 194 | 174 | 10 | 172 | 206 | 162 | 160 | COP64/DHD360 /SD6/QL60 | 61.7 |

| MDEC219/10 | 219 | 199 | 10 | 196 | 234 | 187 | 185 | COP64/DHD360 /SD6/QL60 | 75.1 |

| MDEC245/10 | 245 | 225 | 10 | 222 | 263 | 210 | 208 | COP84/DHD380 /SD8/QL80 | 113.3 |

| MDEC273/10 | 273 | 253 | 10 | 251 | 305 | 241 | 240 | COP64/DHD360 /SD6/QL60 | 137.2 |

| MDEC325/12.5 | 325 | 300 | 12.5 | 298 | 350 | 282 | 280 | DHD112/DHD380 | 209.5/225.5 |

The eccentric overburden drilling system is suitable for drilling water wells, geothermal wells, micro piles, and medium mini-type grouting holes in buildings, dams and harbor projects.

Design PrinciplesThe casing makes the drilling system easy to follow and operate.

Outstanding Advantages:

Simple structure, easy operation, reliable quality, retrievable drilling tools, and long service life.

- As soon as the drilling starts, the reamer opens and enlarges the hole to drive the casing shoe and casing tube down.

- When drilling in over-burden formation is complete, start reverse circulation in order to close the reamer. Then pull up the assembly through the casing tube.

- The casing tube can be left in the hole, or can be pulled out by means of grout sealing material.

- Use the normal drilling tools to drill and achieve the desired depth.