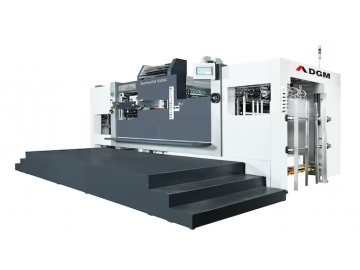

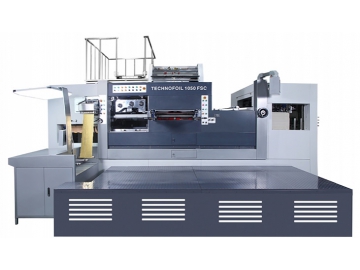

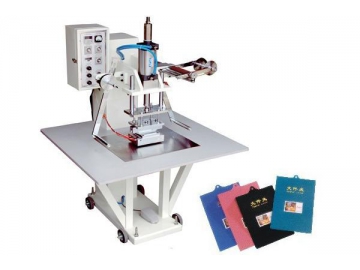

Die Cutting Foil Stamping Press 1050-FC type Hot Foil Stamping Cutting Line

Request a Quote

Hot Foil Stamping Equipment Manufacturer

Description

The 1050-FC type hot foil stamping cutting line is equipped with 4 longitudinal foil pull systems and 2 transverse foil pull systems. It is very suited to run large format die cutting or delicate and multi-layer pattern foil-stamping of different papers, carton boxes, carton boards and corrugated boards.

This foil stamping press also features automatic cooling and die-cutting processes after hot stamping. And the maximum stamping speed can be up to 6000 sheets per hour.

Processed materials- Paper

- Carbon board

- Corrugated board

Processed materials

| Paper | 80 g/m² |

| Maximum carbon board | 2000 g/m² |

| Maximum corrugated board | 4 mm |

| Min. Sheet size | 350 x 400 mm |

| Max. Sheet size | 740 x 1050 mm |

| Speed | 7500 sheets/h |

| Max. Foil stamping speed | 6000 sheets/h |

| Die-cutting force | 300 Ton |

| Max. Longitudinal stamping size | 720 x 1020 mm |

| Max. transversal stamping size | 580 x 1020 mm |

| Max. Die-cutting size | 730 x 1040 mm |

| Heating zones | 12 units |

| Max. temperature | 200 ºC |

| Foil length | 120 to 1200 m |

| Foil width | 50 to 1020 mm (Longitudinal stamping) |

| Foil width | 50 to 630 mm (transversal stamping) |

| Web advance shafts | 4 (longitudinal stamping) |

| Web advance shafts | 2 (transversal stamping) |

| Feeder | 1650 mm |

| Max. Feeder with non-stop | 1270 mm |

| Delivery | 1300 mm |

| L x W x H | 7.08 x4.28x3.26m |

| Weight | 19 Ton |

| Power | 60 kW |

| Compressed air | 6 bar |

| Air compressor capacity | 30 m³/h |

| Air tank capacity | 155 L |

-

Feeder section

- Continuous feeder without interruptions, feeding through pallets or carts

- Material loading by pallets or carts

- Designed with 4 lifting suckers and 4 forwarding suckers, ensuring smooth feeding of cardboard and corrugated board with different thicknesses in an efficient, reliable, and precise manner

- Double sheet detector

-

Register table

- Quick changeovers, easy adjustment for sheet size

- The sheet alignment on the side can be easily made on the register table with guide rails.

- 4 front register lays, independently adjustable

-

Press section

- The die cutter chase is designed with a central positioning system for fast positioning of the die.

- Cutting die with 5 mm thickness

- The pressure can be easily adjusted through the touch screen. Adopting over-pressure protection avoids any damage in the press.

- Available with manual or automatic lubrication system.

- 7 light weight gripper bars

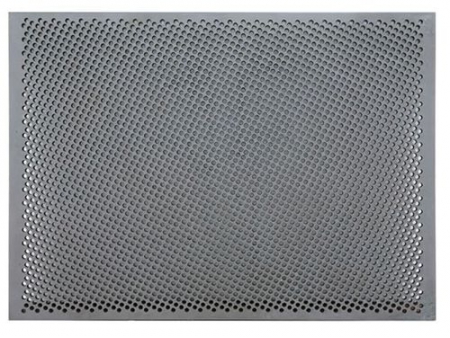

- Changer-over bracket for cutting chase and honeycomb chase.

- Pneumatic lock and release system for cutting chase and honeycomb chase.

-

Foil stamping system

- The heating system features 12 temperature zones with individual temperature control.

- Foil break detector

- Foil fasten device

- Foil unwind device

- Honeycomb chase

-

Delivery section

- Automatic delivery with non-stop curtain

-

Longitudinal foil feeding unit

- 4 foil rolls in a high precision longitudinal foil feeding system

- Air blast foil separation system

- Foil tensioning system

-

Transverse foil stamping system

- 2 foil rolls in a high precision transversal foil feeding system.

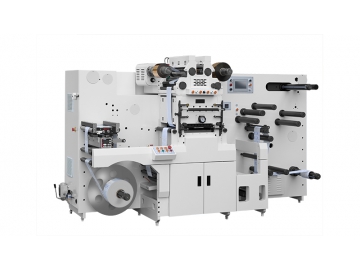

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos