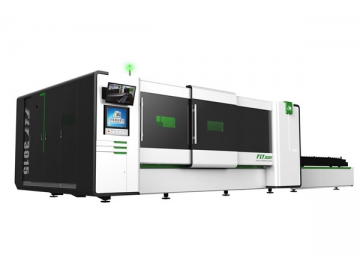

FLY Series Fiber Laser Cutting Machine,FLY3015/FLY4020/FLY6020/FLY8025

Applicable materials

Carbon steel, stainless steel, aluminum alloy, brass and other metal materials.

| Model | FLY3015 | FLY4020 | FLY6020 | FLY8025 |

| Working area | 3000x1500mm | 4000x2000 mm | 6000x2000 mm | 8000 x 2500 mm |

| Laser power | 1000W/1500W/2000W/3000W | |||

| Driving system | High-torque servo, both sides driving system | |||

| Feeding | Automation pallet changer | |||

| Maximum speed | 140m/min | |||

| Maximum accelerated speed | 1.4g | |||

| Position accuracy | ±0.05mm(VDI/DGQ3441) | |||

| Reposition accuracy | ±0.03mm(VDI/DGQ3441) | |||

| Gross power | 10Kw | 11Kw | 12Kw | 12Kw |

| Gross weight | 9.5T | 11T | 13T | 25.5T |

| Overall dimension | 8900x3000x2100mm | 11000x3600x2100mm | 15500x4200x2100mm | 19440x4200x2200mm |

Samples:

Features

1.Equipped with a gantry and a high-strength welded rack. The fiber laser cutting machine undergoes a stress-relieving process making it rigid and prevents deformation.

2.The high-precision servo motor in combination with high-precision drive mechanism provide large transmission torque, small deviation and excellent dynamic performance.

3.Enclosed type outer protection design and CE standard protection glass safety window effectively secure the operators.

4.High-hardness aluminum beam is processed by special technology, achieving light weight and good rigidity.

5.Cast aluminum is adopted for the integrated molding Y-axis sliding plate, which is equipped with an integrated Z-axis system, featuring high precision, quick response and stable operation.

6.Ergonomic design, equipped with intelligent operation terminal, which is user-friendly and easy to operate.

7.Shuttle table features a secure and reliable structure, low failure rate and high efficiency.

8.Built-in remote failure processing function decreases after-sales maintenance costs.