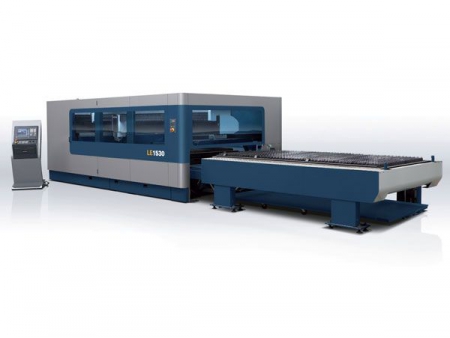

Fiber Laser Cutting Machine

- Fiber laser cutting Machine is turning over a new leaf in the sheet metal processing technology. Accurl fiber laser cutting system is manufactured to meet the demands of fast, high-evolving industry. This machine is manufactured in a flexible design by Accurl's engineers.

- Fiber laser cutting machine is a technological breakthrough in the metal sheet processing field. in order to meet ever changing market demands, our engineers researched and designed this type of cutting machine.

- The machine is user and environment friendly and provides low energy consumption. For instance, the total energy consumption for 2kw laser is 20kw.

- The resonator has a modular structure, which means if you want to change laser from 1kw to 2kw, all you need to do is adding new modules.

- Siemens Sinumerik 840D SL control unit

- Acceleration: 19.6 m/s2 (2G)

- Max. positioning speed: 160m/min.

- Precision: - 0.05 mm.

- Energy efficiency: Greatly reducing power consumption.

- Excellent cutting quality of metal sheets.

- IPG Resonator: Power output from 1 kw to 6 kw.

- Precitec cutting head with power output up to 2kw.

- Precitec HP cutting head with power output of more than 2kw.

- Totally enclosed design and European security standards

- Effective exchange system of high pressure and low pressure gas.

- Capacitive Sensor, high pressure cutting head.

- TCI automatic platform

- Pre-cut film protector.

- Automatic mechanized control system of power output

- Automatic calculation of time and expense

- External network connection

- Automatic pallet exchanger (Included in series models).

- Smoke extraction (Included in series models).

- 3-position reference sensor (Metal sheet rotary detector)

- Piercing Sensor.

- Workpieces and trimmings collecting system.

- Dual proportional valve control system for different gas pressure and special system for high-pressure cutting.

- The laser beam is transmitted to the cutting head via flexible fiber optic cable, ensuring no quality degradation. In this way, excellent cutting quality has been achieved.

- Automatic lateral scrap conveyor

- Linear motion system

- Lighting system.

- Accurl Lazer® Compact Automotive System

- Pipe cutting attachment available on certain models

| Size | 5' x 10' | ||||

| Model Number | NF Pro 510-2 | NF Pro 510-3 | NF Pro 510-4 | NF Pro 510-5 | |

| Resonator | 2 kW | 3 kW | 4 kW | 5 kW | |

| Cutting Capacity ** | Mild Steel (Oxygen) | .625" | .750" | .875" | 1.00" |

| Mild Steel (Nitrogen) | .250" | .250" | .312" | .312" | |

| Stainless Steel | .375" | .500" | .625" | .750" | |

| Aluminum | .312" | .500" | .625" | .625" | |

| Brass | .187" | .250" | .375" | .500" | |

| Copper | .187" | .250" | .312" | .375" | |

| Laser Fiber Diameter * | .004" (100 pm) | .004" (100 pm) | .004" (100 pm) | .004" (100 pm) | |

| Pulse Peak Power | 2 kW | 3 kW | 4 kW | 5 kW | |

| Average Power Consumption (220v/460v 3ph 10%) | 11 kW | 18 kW | 25 kW | 28 kW | |

| Pulse Mode | Freq: 5 - 2000Hz Duty: 0 - 100% | ||||

| Power Stability | ±2‰ (power monitor) | ||||

| Beam Mode | Direct | ||||

| Protection of Laser Beam | Industrial Fiber Cable | ||||

| Laser Gas Composition | N/A | ||||

| Laser Gas Consumption | N/A | ||||

| Cooling Water Flow Rate | 4 gpm (15 l/m) | ||||

| CNC Controller & Operation Panel | Touch Screen, Ethernet Enabled, 4GB RAM with 120 GB HDD Storage | ||||

| Axis Movement | High Speed 4 Axes Servo Motor System | ||||

| Positioning System | Rack and Pinion | Linear | |||

| Axis Speed (X,Y Traverse Speed) | 4,724 IPM (120 m/min) | 7,874 IPM (200 m/min) | |||

| Acceleration | 1.5G | 3G | |||

| Additional Power Consumption | - | 20 kWh | |||

| Repeatability | ±.0007" (± 0.02mm) | ±.0004" (± 0.01mm) | |||

| Positioning Accuracy | ±.002" (± 0.05mm) | ±.0004" (± 0.01mm) | |||

| X, AXIS | 5' (1530mm) | ||||

| Axis | Y,W AXIS | 10' (3050mm) | |||

| Z AXIS | 5.9" (150 mm) | ||||

| Sheet Dimensions | 5' x 10' (1530x3050mm) | ||||

| Maximum Load Capacity | 2,204 lbs (1000 kg) | ||||

| Shuttle Table Change Time | Double pallet system. 27 sec with max sheet weight | ||||

| Z - Axis Distance Control | Non-Contact | ||||

| ASSIST GAS | Mild Steel | Oxygen 1.45 - 87 PSI (0.1-6 Bar) | |||

| Stainless Steel | Dry Air or Nitrogen 2.9 - 362 PSI (0.2-25 Bar) | ||||

| Aluminum | Dry Air or Nitrogen 2.9 - 362 PSI (0.2-25 Bar) | ||||

| Cutting Head | Accurl Auto Focus | ||||

| CAD/CAM Software | RADAN CAD / CAM | ||||

| Machine Dimensions (L×W×H) | 342" x 114" x 90" (8700x2902x2300mm) | ||||

| Machine Weight | 34,172 lbs (15,500 kg) | ||||

*Fiber cables of different diameters are available.

*Due to ongoing product development, Accurl reserves the right to modify any technical specifications and dimensions

*Alternate Optic Configurations: Cutting Capacity may vary depending on optic system settings. Working capacities may be higher or lower depending on the configuration.

*Alternate optic configurations are available. Thus, the cutting capacity and working efficiency may vary depending on the set optic system.

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamp and lantern manufacture, metal processing, ironware, construction, etc.