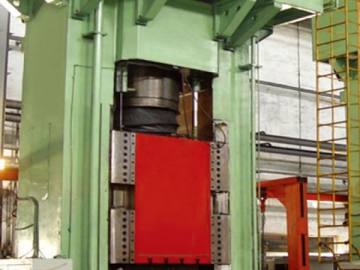

Automated Forging Line for Precision Parts

In order to satisfy the huge market demands and realize mass products, our technical engineers and designers managed to build this automated forging line for precision parts. After a lot of survey and improvement, our forging press line has been serialized and industrialized. This automated line has established a solid foundation in the forging industry because of high automation, low labor cost and high reliability.

Plenty of precision parts produced by our automated forging line have been applied in a vast array of industries.

Main Advantages of Our Forging Press Line 1. Our forging press line provides different options of configurations and realizes a combination of various forging processes, with good molding effects and high product precision.

2. The flexible control system ensures an effective bonding between different processing parts, ensuring high efficiency manufacturing.

3. This forging press line shows a coordinate and orderly arrangement of each processing steps, including material feeding, temperature controlling, cutting, molding, cooling and to name a few.

4. The actual application of our press line will take the working condition into consideration and have a reasonable adjustment, in order to realize the highest possible workshop utilization.

5. This automated forging line has the ability to increase the material utilization by 20%-50%.

6. The advanced molding machines and high processing efficiency effectively decreases our personnel allocation by 40%-60%.

7. In this forging press line, we make use of functional mechanical arm, which ensures a stable transmission of workpieces, short processing time and high efficiency.

8. Compared to normal forging machine, our automated forging line for precision parts are characterized by little labor cost, eco-friendly, energy saving, high efficiency, superior quality and so forth.

9. This automated line is most often applied for the molding and stamping of car clutches, ball valves, pull bars, gear wheels, cross axle and so on.

10. It is also applicable for the finish processing of carbon steel and stainless steel.

11. All operation interfaces provides language and regional options, making it easy for foreign users to operate and maintain.

Technical Data

| JSDY-/-L automated forging line for precision parts | ||||

| Item | Unit | | | |

| Nominal molding force | KN | 3150 | 4000 | 5000 |

| Nominal back pressure | KN | 3150 | 4000 | 5000 |

| Nominal extrusion force | KN | / | / | / |

| Max stroke | mm | 250 | 300 | 300 |

| Stroke of back pressure | mm | 250 | 300 | 300 |

| Extrusion stroke | mm | / | / | / |

| System pressure | MPa | 25 | 25 | 25 |

| Molding speed | mm/s | 30-60 | 30-60 | 30-50 |

| Speed of empty trip | mm/s | 260-330 | 260-330 | 260-330 |

| Speed of return trip | mm/s | 230-270 | 230-270 | 220-270 |

| Molding efficiency | s.p.m | 9-12 | 8-12 | 7-10 |

| Workpiece weight | KG | 1.8 | 2.3 | 2.5 |

| Installed power | KW | 100 | 123 | 151 |

| Heating power | KW | 250 | 300 | 350 |

| Max shearing diameter | mm | 30 | 50 | 60 |

| Molding steps | Steps | 3 | 3 | 3 |

| Automatic conveyor | / | Yes | Yes | Yes |

| Robot | / | Yes | Yes | Yes |

| Automatic cooling system | / | Yes | Yes | Yes |

| Processing material | / | Stainless steel, carbon steel, copper alloy, aluminum alloy | ||

| JSDY-/-L automated forging line for precision parts | |||||

| Item | Unit | | | | |

| Nominal molding force | KN | 6300 | 8000 | 4000 | 5000 |

| Nominal back pressure | KN | 6300 | 8000 | 4000 | 5000 |

| Nominal extrusion force | KN | / | / | 2000 | 3150 |

| Max stroke | mm | 400 | 400 | 300 | 300 |

| Stroke of back pressure | mm | 400 | 400 | 300 | 300 |

| Extrusion stroke | mm | / | / | 150 | 150 |

| System pressure | MPa | 25 | 25 | 25 | 25 |

| Molding speed | mm/s | 25-50 | 25-45 | 30-40 | 30-40 |

| Speed of empty trip | mm/s | 260-320 | 260-320 | 260-330 | 260-330 |

| Speed of return trip | mm/s | 200-250 | 200-250 | 230-270 | 250-270 |

| Molding efficiency | s.p.m | 7-10 | 6-9 | 8-12 | 7-10 |

| Workpiece weight | KG | 3.2 | 3.5 | 2.2 | 2.4 |

| Installed power | KW | 183 | 197 | 123 | 151 |

| Heating power | KW | 400 | 450 | 300 | 350 |

| Max shearing diameter | mm | 70 | 90 | 50 | 60 |

| Molding steps | Steps | 3 | 3 | 2 | 2 |

| Automatic conveyor | / | Yes | Yes | Yes | Yes |

| Robot | / | Yes | Yes | Yes | Yes |

| Automatic cooling system | / | Yes | Yes | Yes | Yes |

| Processing material | / | Stainless steel, carbon steel, copper alloy, aluminum alloy | |||