Hydraulic Flanging Machine

Request a Quote

NCM-110

Automatic folding machine for metal door panels

NCM-110 hydraulic flanging machine is ideal for steel and stainless steel door panels that utilize fully automatic flanging technology to shape the upper and lower ends of the front and back panels of the door leaf. It achieves folding of various steel door panels at both ends through hydraulic flanging with dual-mold forming units at both sides. This metal door panel machine features fully automatic flanging operation, with a maximum production speed of up to 10m/min. With just one machine, the forming of the door leaf can be completed.

- Before forming

- After forming

- Upper side

- Lower side

Applications

- Security doors

- Fire-rated doors

- Healthcare/hospital doors

- Cleanroom doors

Technical Parameters

| Material thickness | 0.8-1.0mm |

| Material width | 300-1200mm |

| Applicable material | Galvanized sheet,cold-rolled sheet,hot-rolled sheet,color-coated sheet,stainless steel |

| Tool changing method | Manual/automatic (optional) |

| Flanging method | Unidirectional flanging/bi-directional flanging (optional) |

| Production speed | 8-10m/min |

| Main power | 5.5kW |

Features

- Fully automatic flanging allows one person to operate multiple machines.

- Automated operation requires no additional material storage area required.

- One machine can complete the forming of door panel sides.

- Sheet metal appearance can be added as needed.

Details

-

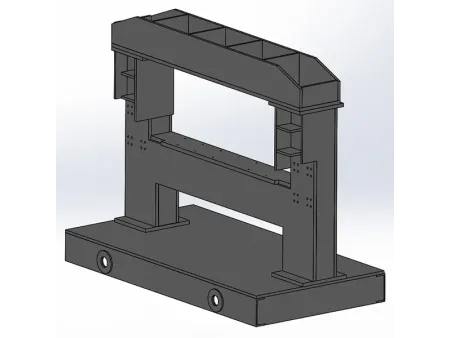

Main Machine Frame

The frame and crossbeam are welded by Q235 steel plate and processed by CNC gantry milling to ensure the accuracy and horizontality of the workpiece. -

Pressing Device

The pressing device adopts a swing arm structure, once clamped, it is not easy to retreat the material, ensuring the accuracy of the flanging width.

The pressing tool width is convenient to adjust. If equipped with a servo motor, independent tool changing can be achieved.

The pressing device uses hydraulic pressurization for greater force and more stable operation. -

Flanging Device

The flanging device can be optionally equipped with a unidirectional flanging tool (folding from bottom to top) or a bidirectional flanging tool (can fold from bottom to top and from top to bottom).

The flanging angle can be adjusted through positioning screws, providing convenience in the adjustment process.

The flanging device adopts hydraulic transmission, delivering greater force and more stable operation. -

Flanging Mold

The flanging mold is made of Cr12Mov material, ensuring one-step molding.

The flanging mold can be optionally equipped with a 90° tool (only capable of folding at 90° angle) or a forming tool (capable of directly performing one-step folding), offering greater versatility. -

Discharge Table (Optional)

The discharge table is equipped with a height adjustment device to adjust the height as needed.