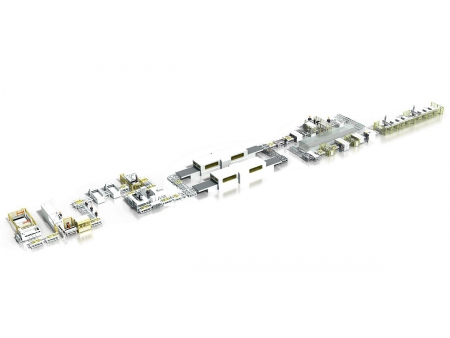

EPS Sandwich Panel Production Line

The color steel sandwich plate compound production line can compound the corrugated plates in a single step. The entire production line is composed of the feed unrolling system, molding system, cutting device, compounding system (rib pressing, glue coating, heating, compounding, and flanging, notching, trimming, pneumatic and automatic cutting. The process is all computer controlled, and this system is necessary for producing faceplates and wall boards for industrial workshops and warehouses.

Power Supply: AC380/50-60HZ

Total Power: 32 KW

Production Line Speed: 0-4.05m/min

Equipment overall dimensions: 45000x3000x2800

Product width: 1000mm, 1200mm (or depend on)

Product Thickness: 50-250mm

Annual Output: 600000m2

Applications

Roof Wall Sandwich Panel, Insulated Sandwich Panel, Prefabricated House, Prefab House, Mobile House, Cool Room

Our advantage

High Quality

Reliable

Durable

Reasonable price

Excellent after-sales service

1 year warranty

More than 18 years of experience