Pressure Measurement

Our pressure measurement instrument workshop is mainly responsible for producing gauge pressure transmitters, pressure gauges, and differential pressure gauges. According to client-side requirements and application environments, we can offer tailor-madepressure measuring instruments. We can also offer selection guides.

The gauge pressure transmitter is mainly composed of the pressure sensor, measuring circuit, and process connectors. It can convert gas or liquid pressure, which are sensed by the pressure sensor, into standard electrical signals, such as 4~20mADC, etc.

The differential pressure transmitter is designed to measure the pressure difference between its two ends.In order to prevent mediums in pipelines entering into the transmitter, the pressure sensing diaphragm and the transmitter is connected by capillary tubes filled with fluids.

The gauge pressure transmitter supports accurate measuring of liquid level and medium density for various vessels. It is available in plate flange and insert flange versions, and is applicable for high viscosity mediums or liquid suspensions.

This selection of differential pressure transmitter features remote diaphragm seal, and thus it is also called remote seal transmitter. While adopting imported key raw material, key components and parts, etc., the whole unit undergoes strict assembly and testing.

This line of pressure transmitter has strong anti-overload performance and impact resistance. Its overload capacity is multiple times of its measuring range. Even direct knocking on measuring elements cannot damage the pressure transducer, and won't cause bad influence on measuring accuracy.

Diffused silicon pressure sensor is often used in industries with high demands on automation, including heat supply, refrigeration, chemical engineering, coal mining, petroleum, food processing, water supply, etc.

The pressure gauge is designed with stainless steel housing and silicon rubber seals, and thus has great performance in dust prevention, moisture resistance and vibration resistance. It can be installed and used in any harsh environments.

It is typically used for fluid pressure measurement purpose in technological processes with high demand on corrosion resistance and anti-vibration performance. Due to our adoption of special stainless steel, the pressure gauge is the optimum pressure measuring device for corrosive mediums under harsh environments.

The outstanding feature of this pressure gauge is that it offers stable performance in machine tools or equipment with strenuous vibration. The level of shock resistance is up to V., H.4 or V.H.5, upon request.

The diaphragm pressure gauge is designed for pressure measurement or negative pressure measurement purposes. It is a popular selection of industrial instrumentation for corrosive, viscous mediums, as well as various non-crystallizing, non-solidifying fluids.

This pressure gauge is used for oxygen pressure measurement. It is prohibited to contact oil and grease.

The electrical contact pressure gauge is a popular selection of industrial instrumentation, designed for the purpose of fluid pressure measurement. Applicable for various non-explosive liquids, it is often found in industrial equipment sets and industries such as petroleum, chemical, metallurgy, power generation, etc.

Our range of differential pressure gauge has earned a high reputation in industries such as offshore oil engineering, chemical, power generation, mechanical and metallurgy.Static pressure refers to the designed pressure of pipeline on measuring points, and it is one of the necessary data that needed for pressure gauge selection.

This differential pressure gauge offer customers an ideal pressure measuring solution for high static pressure applications. It is compatible with liquids and gases which are non-crystallizing, non-solidifying, and not corrosive to stainless steel.

- Pressure Measuring Instrument Workshop

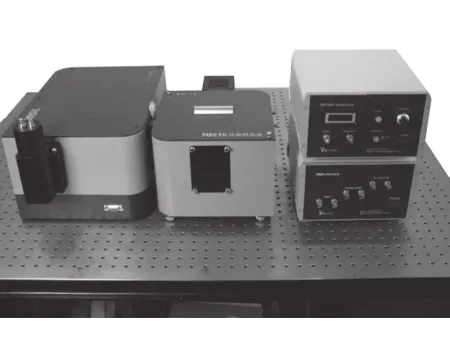

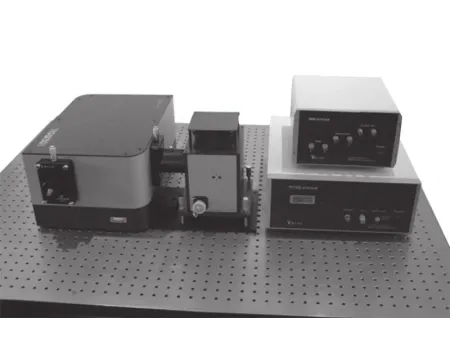

- Assembly

- Calibration

- Testing

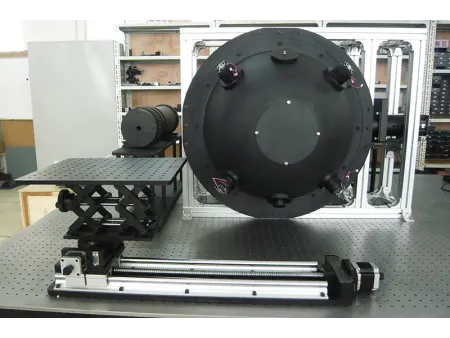

Oil filling

Oil filling