Your trusted partner for bagging and palletizing systems

GS-9 SERIES

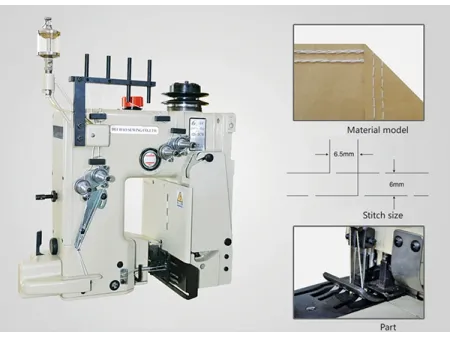

Bag closing head for stitching open-mouth bags with speed up to 2700RPM

Maximum Speed 2700 RPM, Operating Speed 2500 RPM

The high-speed bag sewing head works well with fast bagging lines that run at around 25 meters per minute and can handle different types of open-mouth bags. The built-in sealed oil chamber keeps the moving parts running smoothly, and the dust protection helps them wear more slowly. This makes the sewing head more durable and reduces how often maintenance is needed.

| Stitch length adjustment | 7-10.5mm |

| Stitch type | 2-thread chain stitch (401) |

| Needle model | DR-H30 #26 |

| Cutter type | paper bag cutter |

| Machine weight | 42kg |

| Machine dimensions (L×W×H) | 410×250×400mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Maximum Speed 2700 RPM, Operating Speed 2500 RPM

When thicker or more slippery bag materials need better control during stitching, the GS-9CU sewing head offers an upgraded option developed from the GS-9C model. It uses a single-needle, double-thread chain stitch and features top-and-bottom synchronized feeding, which allows both sets of feed dogs to move the bag at the same time. The synchronized feeding keeps the bag moving steadily through the sewing area, which allows for longer stitch settings when needed, and helps maintain good efficiency at speeds up to 2700 rpm, with around 2500 rpm as the usual operating pace. The built-in oil chamber takes care of the lubrication automatically, helping the main components run smoothly during long hours of use.

| Stitch length adjustment | 7-11.5mm |

| Stitch type | 2-thread chain stitch (401) |

| Needle model | DR-H30 #26 |

| Cutter type | paper bag cutter |

| Machine weight | 42kg |

| Machine dimensions (L×W×H) | 410×250×400mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Maximum Speed: 2500 RPM, Operating Speed: 2300 RPM

Stronger seam control and better closure performance are achieved with the GS-9CW high-speed two-needle four-thread bag sewing head, a reinforced design developed from the GS-9C high speed sewing head. With its two-needle, four-thread design, the sewing head forms two seams at once, helping keep the contents from leaking and giving the bag a stronger finish. Consistent stitch length and spacing support smoother, more efficient operation, and the built-in oil reservoir provides steady lubrication for reliable performance during long production runs.

| Stitch length adjustment | 7-10.5mm |

| Stitch type | 2-thread chain stitch (401) |

| Needle model | DR-H30 #26 |

| Cutter type | paper bag cutter |

| Machine weight | 42kg |

| Machine dimensions (L×W×H) | 450×250×400mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Maximum speed 2700 RPM, Operating speed 2500 RPM

The semi-automatic bag sewing head with thread-trimming features a hand-activated mechanical cutter and operates at high speed with low noise, offering long service life in daily use. It is suitable for packaging lines in grain processing, chemical production and port facilities, and can sew open-mouth bags made of materials such as paper, woven plastic and jute. The sewing head has a vertical design and uses a sealed oil chamber to keep the main parts running smoothly. It also has dust-protected needle bearings that help slow down wear, so it doesn’t need frequent maintenance in daily use.

| Stitch length adjustment | 7-11.5mm |

| Stitch type | 2-thread chain stitch (401) |

| Needle model | DRG-67 #27 |

| Cutter type | paper bag cutter |

| Machine weight | 42kg |

| Machine dimensions (L×W×H) | 470×250×400mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Maximum speed 2700 RPM, Operating speed 2500 RPM

The single-thread bag sewing head runs at high speed with low noise and is a practical option for packaging lines in grain processing, chemical plants and port operations. It can work with different types of open-mouth bags, including paper sacks, woven plastic and jute. It has a vertical design and uses a sealed oil chamber to keep the moving parts lubricated. Its dust-protected needle bearings help slow down wear, which means less maintenance and more stable performance in a variety of working environments.

| Stitch length adjustment | 7-11.5mm |

| Stitch type | 2-thread chain stitch (401) |

| Needle model | DR-H67 #27 |

| Machine weight | 42kg |

| Machine dimensions (L×W×H) | 470×250×400mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.