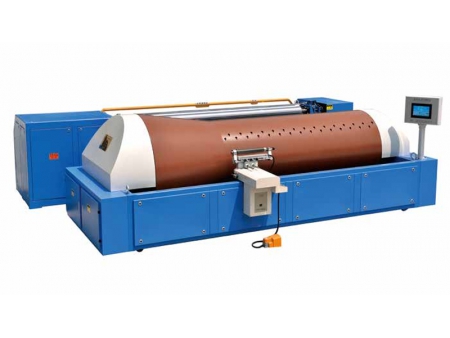

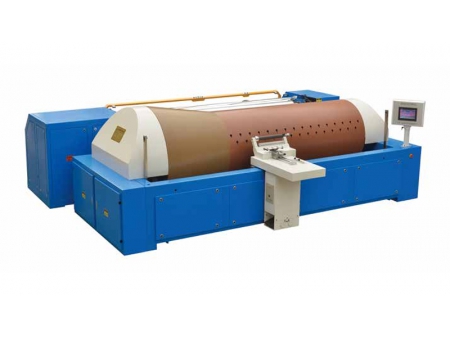

KGA215H High-Speed Sectional Warping Machine

Request a Quote

Our high-speed sectional warping machines use a combination of dual servo motors, double linear guide rails, double yarn guide rollers, and ball screws to ensure smooth, accurate control. The beam winding system includes a durable reducer and reinforced support rails, keeping everything stable even at high speeds. This setup works well with both spun and synthetic filament yarns. It supports warping speeds of up to 800 m/min and beam winding at 300 m/min—ideal for high-precision weaving preparation.

Features

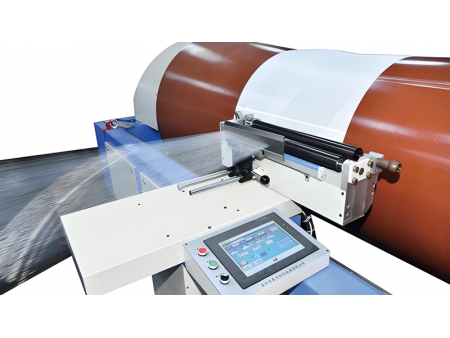

- Equipped with dual linear guide rails, with upper and lower ball screws driven independently by two servo systems for precise and stable control.

- Two AC servo motors and corresponding drives provide reliable transmission performance during high-speed operation.

- Forward and backward movement of the warping table is achieved through an independent stepper motor and ball screw mechanism, which allows evenly spaced winding.

- Axial positioning of the warping head is controlled by a high-precision servo motor, enabling automatic start point and stripe alignment at the press of a button.

- Integrated computer and PLC systems offer intelligent features such as yarn break memory and automatic stop when the preset length is reached.

Machine specifications

| Warping speed | 0~800m/min |

| Beaming speed | 0~300m/min |

| Drum diameter | 1026mm |

| Drum length | 2300mm |

| Cone angle | 9° (1: 6.3) |

| Cone length | 1210mm |

| O.D. runout | ≤ 0.10mm |

| Guide rail | Ball linear guide rail (pair of upper and lower rail) |

| Section traverse speed | 0.001-9.999mm/r |

| Section traverse accuracy | ±0.01% |

| Yarn/start alignment | Automatic |

| Length of yarn guide roller | 500mm |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos