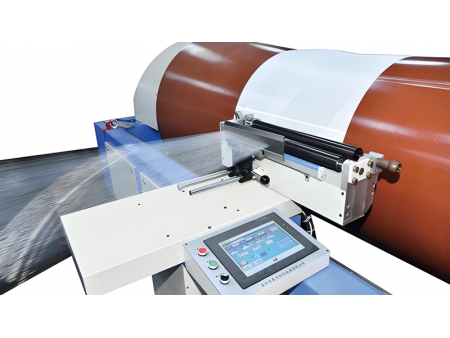

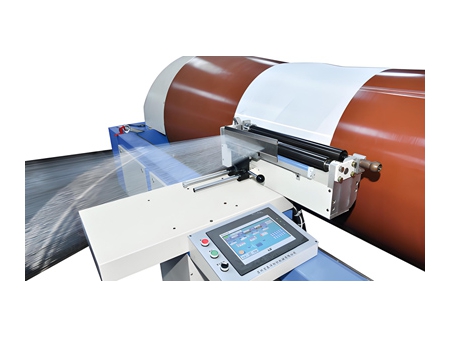

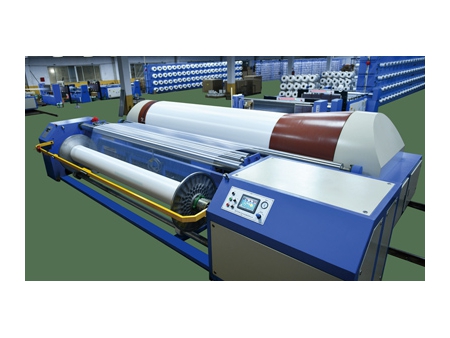

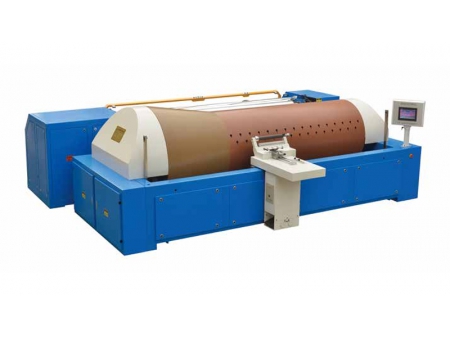

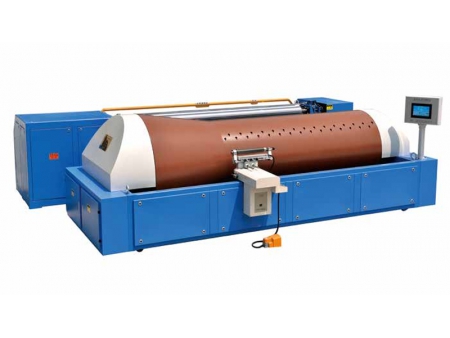

KGA388 Intelligent Sectional Warping Machine (Mother Yarn)

Request a Quote

This sectional warping machine simplifies the processing of mother yarn by combining slitting and warping into a single step. Yarn is prepared for weaving directly after beaming, shortening the overall workflow and improving efficiency. Consistent yarn tension is maintained throughout the process, ensuring stable performance and quality. Suitable for use with water jet, air jet, and rapier looms, it meets the needs of operations that prioritize streamlined production and fabric precision.

Features

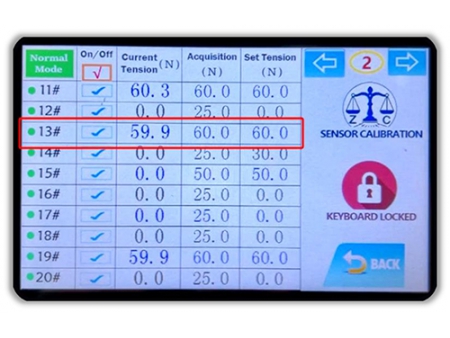

- The entire warping process is automated with intelligent control, reducing manual operations and improving overall production efficiency.

- Stable yarn tension is maintained throughout the process, minimizing yarn breakage and ensuring consistent warping quality.

- Wide speed adjustment range allows compatibility with different mother yarn types, thicknesses, and specifications.

- Compact and structurally optimized design reduces floor space requirements while maintaining operational stability and aesthetic appeal.

- Equipped with yarn break sensors and static eliminators, the system ensures safe operation and automatic stop in case of abnormalities.

- Supports a wide range of synthetic mother yarns, including polyester and nylon. Yarn size and spindle configurations can be customized based on specific production needs.

Machine specifications

| Working width | 2300-4000mm |

| Beam flange diameter | 800,1000mm |

| Warping speed | 0-800m/min |

| Beaming speed | 0-150m/min |

| Braking distance | ≤5m |

| Beam tension | ≤12000N |

| Cone length | 1010,1360mm |

| Section traverse speed | 0.001-9.999(mm/r) |

| Input voltage | 3x380V(±10%) |

| Tension roller | S type design |

| Bobbin number | 120,136pcs |

| Single yarn spindle control | Torque motor |

| Layer number | 4 Layers |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos