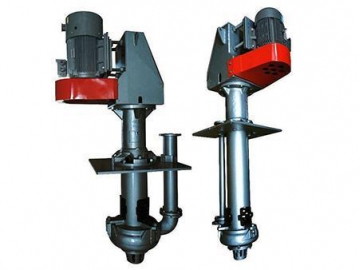

Vertical Centrifugal Sump Pump

Vertical Centrifugal Sump Pump, EVM Type

EVM type vertical centrifugal sump pump’s body is wear resistant metal. With rubber lined spare parts immersed under liquid, our product is suitable for transporting corrosive slurry.

The vertical centrifugal sump pump is designed to meet the special installation environment, which can be immersed under liquid to work. Even under the working conditions of inadequate suction volume, our product can also work normally without any shaft seal and seal water. By adoption of single casing structure, this pump is characterized by light weight, small size, convenient to install and maintain, etc.

In accordance with the surface level of sump pump basin, our customers can choose different lengths of pump drive shaft and suction tube. Furthermore, it keeps running in the best working conditions with long service life and highly effective operation to meet a variety of poor transport conditions.

EVM(R) Series Performance Chart

| Model | Allowable Max Power P( kW ) | Clear Water Performance | Impeller | ||||

| Capacity Q | Head H(m) | Rotate Speed n(r/min) | Top Efficiency η% | Impeller Diameter D(mm) | |||

| M 3 /h | I/s | ||||||

| EVM(R)-40P | 15 | 17-43.2 | 4.7-12 | 4-28.5 | 1000-2200 | 40 | 188 |

| EVM(R)-65Q | 30 | 18-114 | 5-32 | 5-31.5 | 750-1500 | 60 | 280 |

| EVM(R)-100R | 75 | 54-289 | 15-80 | 5-36 | 500-1200 | 62 | 370 |

| EVM(R)-150S | 110 | 108-479 | 30-133 | 8.5-40 | 500-1000 | 52 | 450 |

| EVM(R)-200S | 110 | 189-891 | 52.5-247.5 | 6.5-37 | 400-850 | 64 | 520 |

| EVM(R)-250T | 200 | 360-115 | 2100-320 | 7-33 | 400-750 | 60 | 575 |

| EVM(R)-300T | 200 | 540-1548 | 150-430 | 5.5-26 | 350-700 | 60 | 580 |

Advantages

Scope of Applications

The vertical centrifugal sump pump is suitable for the transmission of slurry with corrosive property, coarse granule and high concentration, widely applicable to metallurgy, mining, coal, electricity, building materials, environmental protection and other departments.

Note

Different sump pumps have distinct depth scopes when immersed under the water, which depends on the parameters of working conditions and the detailed models of pump.

Model Explanation

E: Excellence

V: Vertical Slurry Pump

M (Anti-abrasive metal lined), R (Rubber lined)

40: Discharge Size (mm)

P: Frame Type

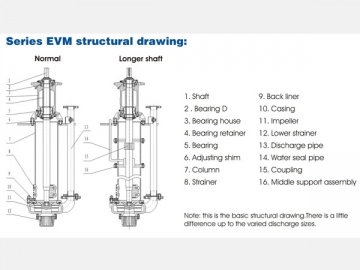

Structural Diagram

Series EVM structural drawing:

1.Shaft 9.Back liner

2.Bearing D 10.Casing

3.Bearing house 11.Impeller

4.Bearing retainer 12.Lower strainer

5.Bearing 13.Discharge pipe

6.Adjusting shim 14.Water seal pipe

7.Column 15.Coupling

8.Strainer 16.Middle support assembly

Note: this is the basic structural drawing.

There is a little difference up to the varied

discharge sizes.

Related Names

Heavy Duty Pump | Quiet Sump Pump | Chemical Transfer Pump