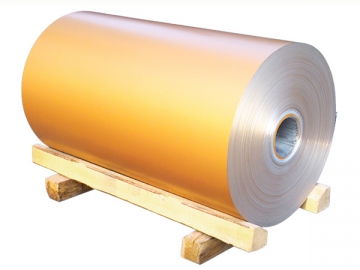

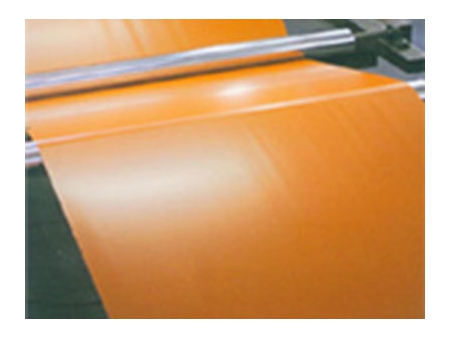

Anti-scratch Coated Aluminum Coil

Anti-scratch Coated Aluminum Coil

Performance and Usage

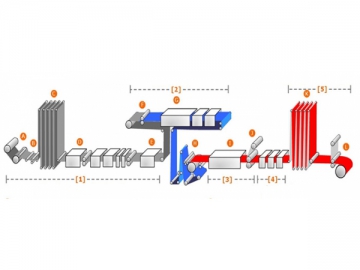

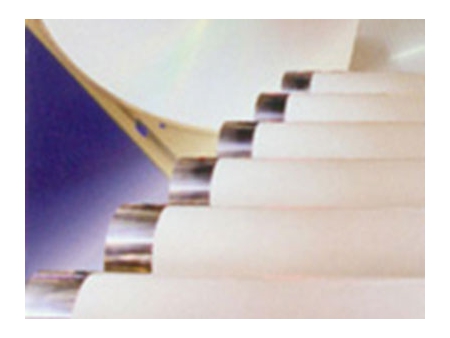

Anti-scratchcolor coated aluminum coil is made from the world's most outstandinghigh-performance polyester paints and high-alloy series aluminum. Because ofthe special processing way, it has excellent abrasion resistance andanti-scratch performance, and has all the advantages of PE coating formingperformance.

It can be widely used inairports, subway, shopping malls and other public places decoration, also beused in rolling shutter doors and windows and other products.

美工放图:抗刮s.jpg

Performanceof the coating

| Aluminum Thickness | Coating Thickness | MEK | T-Bend | Impact | Adhesion | Pencil Hard-ness | Abrasion resistance | Boiling Water Proof |

| 0.3-1.5 ㎜ | ≥18μm | ≥100 Times | ≤1T | 50 ㎏ • ㎝ | Grade 0 | ≥3H | More than 1200 rounds | no change within 2 hours e |

| 0.2-0.28 ㎜ | ≥18μm | ≥100 Times | ≤1T | 30 ㎏ • ㎝ | Grade 0 | ≥3H | More than 1200 rounds | no change within 2 hours |

The Performance of Anti-Scratch CoatedCoil

| Item | Test Item | Standard | National Standard | Test Result |

| 1 | Color difference | ECCA T3 | Δ E ≤ 2.0 | Δ E ≤ 1.0 |

| 2 | Gloss | ECCA T2 | Difference ≤ 10 | Difference ≤ 5 |

| 3 | Coating thickness | ECCA T1 | ≥ 14µm | ≥ 16µm |

| 4 | Pencil hardness | ECCA T4 | ≥ HB | ≥ 2H |

| 5 | T-bend | ASTM D4145 | ≤ 3T | 0T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥ 20kgNaN | ≥ 30kgNaN |

| 8 | Boiling water Resistance | GB/T17748 | 2hrs No change | 2hrs No change |

| 9 | Solvent resistance | ASTM D2248 | 200 times paint remaining | 200 times paint remaining |

| 10 | Abrasion resistance | ASTM D4060 | No requirements | 500g*2 , 1000 circles Film wastage ≤ 30mg |