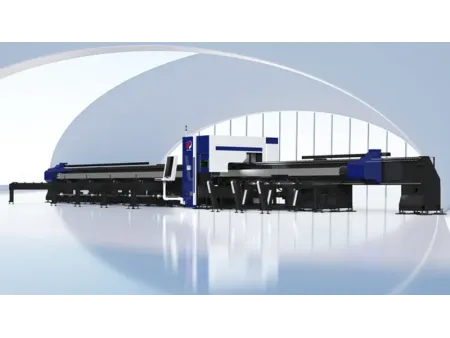

WHIRL PLUS C Series Laser Tube Cutting Machine

Laser cutter system for handling tubes and profiles

The WHIRL PLUS C series laser tube cutting machine, a standout in subway manufacturing technology, boasts an efficient automatic loading and unloading mechanism for a seamless, intelligent cutting experience with tubes. This advanced metal cutting tool not only automates the handling of subway pipes, minimizing manual loading risks but also features synchronous feeding to reduce wait times and boost productivity. Equipped with WPC9036 and WPC12036 pneumatic square chucks, alongside WPC12050 pneumatic circulation chucks, it ensures a stable, efficient cutting process.

- Laser power6,000W-20,000W

- X axis travel9500mm/12500mm/12700mm

As a leader in the Chinese laser industry, PENTA LASER specializes in the design and manufacture of high performance laser machines for a wide range of industries, including automotive, shipbuilding, agricultural machinery. Contact with us for a full custom laser engineering solution.

- Shipbuilding

- Automotive

- Construction

- Underground Railway

- Piping & Ducting

- Energy Equipment

- Metalworking

| Laser power | 6,000W-20,000W |

| X axis travel | 9500mm/12500mm/12700mm |

| Tube weight | 1200-3000kg |

| A/P axis rotation | N×360° |

| Maximum speed of linear motion axis | 72m/min, 72m/min, 45m/min |

| Maximum speed of rotary motion axis | 75rpm/75rpm/45rpm |

| Maximum loading capacity | 100kg/m, 100kg/m, 200kg/m |

- Intelligent Semi-Automatic Loading and Unloading: Facilitates smart, semi-automatic processing of subway pipes, reducing manual handling and enhancing workplace safety.

- Advanced Configurations: Equipped with C9036 and WPC12036 pneumatic square chucks, and WPC12050 pneumatic circulation chucks for optimized performance.