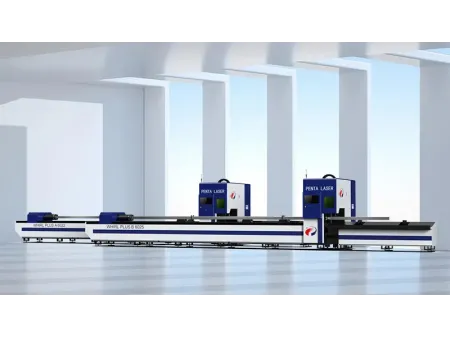

WHIRL PLUS A&B Series Laser Tube Cutting Machine

Laser cutter system for handling tubes and profiles

The WHIRL PLUS A&B Series laser tube cutting machine features automatic operation with excellent adaptability, offering precise handling of long tubes via its automatic clamping and focusing technology. This machine excels in processing a variety of tube types, including square, round, and rectangular tubes. Its intelligent design, augmented with nesting software, boosts cutting design flexibility. Users can opt for an automatic loading and unloading system to minimize labor costs while significantly enhancing cutting efficiency. The machine offers tube remnant cutting and an optional bevel cutting feature, delivering efficient, smart, and precise cutting solutions to its users.

- Laser power3,000W-6,000W (optional)

- X axis travel 6200mm (depending on machine model)

As a leader in the Chinese laser industry, PENTA LASER specializes in the design and manufacture of high performance laser machines for a wide range of industries, including automotive, shipbuilding, agricultural machinery. Contact with us for a full custom laser engineering solution.

- Heavy Machinery

- Structural Steel

- Furniture

- Agricultural Machinery

- Fitness Equipment

- Piping & Ducting

- Our WHIRL PLUS A&B Series laser tube cutting machine boasts intelligent semi-automatic and fully automatic loading and unloading systems (optional) capable of handling up to five tons per bale, with a maximum single feed of 300KG, ensuring unparalleled production efficiency.

- They offer a versatile range of cutting capabilities including straight cutting, punching, bevel cutting, and fish-mouth cutting to meet diverse needs.

- Capable of processing a wide array of materials, including round pipes, square pipes, I-beams, H-beams, and channel steels, our equipment caters to comprehensive cutting requirements.

| Laser power | 3,000W-6,000W (optional) |

| X axis travel | 6200mm (depending on machine model) |

| A/P axis rotation | N×360° |

| Linear motion axis repeatability | ±0.03mm |

| Quantity of chuck | 2 |

| Tube diameter | Round tube □20-150mm ○20-240mm |

| Square tube □20-240mm ○20-240mm | |

| Tube weight | 200-400kg |