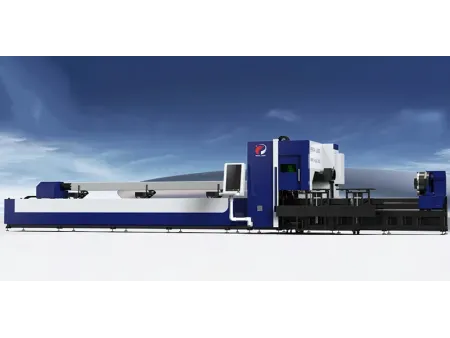

WHIRL PLUS L Series Laser Tube Cutting Machine

Laser cutter system for handling tubes and profiles

Our WHIRL PLUS L series laser tube cutting machine integrates advanced servo follow-up support, delivering efficient and precise cuts across various pipe diameters. Featuring an intelligent loading system with both semi-automatic and fully automatic options, this series streamlines the tube bundle loading process, significantly cutting down on labor costs. With its user-friendly interface and straightforward operation, the WHIRL PLUS L series offers superior cutting performance and operational ease, positioning it as an ideal choice for professionals in the pipe cutting sector.

- Laser power3,000W-6,000W

- Y axis travel6700mm / 9500mm / 12700mm

As a leader in the Chinese laser industry, PENTA LASER specializes in the design and manufacture of high performance laser machines for a wide range of industries, including automotive, shipbuilding, agricultural machinery. Contact with us for a full custom laser engineering solution.

- Shipbuilding

- Automotive

- Construction

- Underground Railway

- Energy Equipment

- Metalworking

| Y axis travel | 6700mm / 9500mm / 12700mm |

| Tube diameter | Square tube □20-240mm ○20-240mm (Optional round chuck) |

| Tube weight | 400-800kg |

| Laser power | 3,000W-6,000W |

| Linear motion axis repeatability | ±0.03mm |

| A/P axis rotation | N×360° |

| Maximum speed of linear motion axis | 90m/min |

| Maximum speed of rotary motion axis | 100rpm |

- The WHIRL PLUS L series laser tube cutting machine is outfitted with a servo follow-up support, ensuring compatibility with a diverse array of pipe diameters.

- The servo bracket, equipped with a buffer cylinder, delivers outstanding stability and achieves high-precision cuts.

- Available semi-automatic and fully automatic loader options enhance productivity and lower labor expenses, streamlining your production process.

- Servo Follow-up Support: Compatible with varied pipe diameters, this feature ensures utmost pipe stability and precision in cutting.

- Servo Bracket: Comes with a buffer cylinder to enhance both stability and the accuracy of cuts.

In laser cutting systems, the power output of the laser tube hinges on:

- Length of the Laser Tube: Generally, a longer laser tube signifies higher power capability.

- Diameter of the Laser Tube: A larger diameter equates to greater power output.