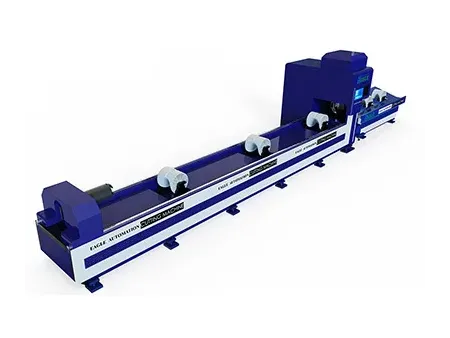

Fiber Laser Tube Cutting Machine

This fiber laser tube cutting machine is a versatile and efficient tool designed for cutting and processing round tubes, square tubes, rectangular tubes, angle iron, channel steel, H-beams, and various other profiles. This makes it a suitable choice for diverse applications, from heavy-duty industrial tasks to more intricate fabrication. It can handle round tubes with diameters ranging from Ø15 to Ø220mm and square tubes with diameters from Ø10 to Ø160mm.

This laser cutting machine is widely used in industries such as kitchenware, lighting, automotive, fitness equipment, and hardware, where precise metal and tube processing are essential. It can load single tubes weighing up to 374 pounds (170 kilograms), offering metal manufacturers increased production capacity and efficiency.

-

- Laser cutting of aluminum square tube

-

- Laser cutting of stainless steel tube

-

- Laser cutting of carbon steel angle

-

- Laser cutting of stainless steel square tube

-

- Laser cutting of stainless steel workpiece

-

- Laser cutting of stainless steel part

| Effective Length of Working Area | 6000mm |

| Positioning Accuracy | ±0.05mm/m |

| Repeatability | ±0.03mm |

| Max. Speed | 1.2G |

| Phase | 3 |

| Rated Voltage/Frequency | 380V/60Hz |

| Protection Level | IP54 |

| Round Tube | 20-230mm |

| Square Tube | 20×20mm-200×200mm |

| Control System | CypCut |

| Laser Power | 3000W |

| Min. Tailing Length | < 150mm |

The fiber laser tube cutting machine features a large bore chuck and automatic loading and unloading capabilities, ensuring high safety during operation. The tube alignment and positioning precision is 0.005mm, and the clamping accuracy is less than 0.1mm.

This laser tube cutting machine is designed to allow the tube to be inserted deeply into the front chuck, enabling ultra-short tail material cutting with precise cuts and increased material utilization rate. Additionally, the chuck jaws have a special friction surface that securely grips the tube, preventing it from slipping during the cutting process.

- Machine Bed

The machine bed is constructed from welded steel plates and undergoes a full annealing process to eliminate internal stress. This ensures excellent rigidity, stability, and resistance to deformation.

- Laser Source

Equipped with a Chuangxin laser source, the laser tube cutting machine boasts an optical-to-electrical conversion efficiency of over 30%, allowing for continuous processing of various metal sheets.

- Laser cutting head

Featuring a compact, integrated design, the laser cutting head connects with the machine's control system via Bluetooth. It is also capable to monitor the pressure of the gas and the laser cutting head, providing real-time data display.

- Water Chiller

The professional-grade water chiller has a high-performance and a low-noise design. The internal water tank is made of stainless steel, while the external sheet metal is coated with an anti-rust electrostatic spray, effectively preventing corrosion and prolonged longevity.

- Wireless Control Handle

The wireless control handle offers language options in both Chinese and English, increasing the convenience of the usage of this cutting machine. Its magnetic back design allows it to be easily attached to the side of the electrical control cabinet or the top of the machine, making operation intuitive and reducing the risk of misplacement.

- Chuck Clamping System

The system features a high-precision six-level ground rack and a high-accuracy chuck. The sliding surfaces of the chuck jaws are hardened to increase its resistance to wear and precisely ground for smooth operation and accurate clamping. The machine is also equipped with a lubrication system that supports automatic oiling, effectively extending the equipment's lifespan by reducing friction, wear, and the need for manual maintenance.

- Dust Collector

The patented compartmentalized dust extraction system is designed using airflow simulation technology to achieve a highly efficient dust removal process. Testing has shown that the dust extraction rate exceeds 75%, compared to the standard 30%, giving more effective results.

Yes, we can customize the laser machine to meet your specific requirements, including size, power, and additional features.

Regular maintenance includes cleaning the laser, checking optical components, and ensuring that the machine's lubrication and cooling systems are functioning properly.

Typically, you will need a laser cutting head, cutting software, and a cooling system, among other accessories and equipment.

Yes, we provide installation, commissioning, and operational training to ensure that you can correctly operate and maintain the tube cutting machine.