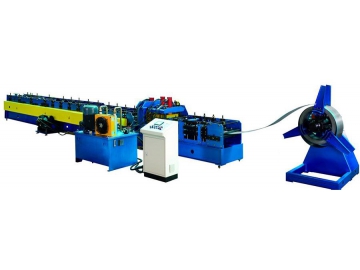

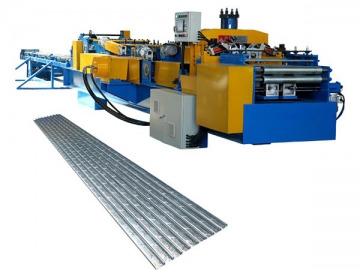

Cee Purlin Roll Forming Machine

The fully-automatic cee purlin roll forming machine incorporates an active feeding roll, a leveling unit, side pressing rolls, a rollforming unit, a cutting unit, a hydraulic power unit and a control panel etc. It is a cold roll forming machine intended for making all kinds of cold-formed steel materials and a wide range of profiles that possess uniform wall thickness and complicated cross sections.

Features of the Cee Purlin Roll Forming Machine

1. Roll-formed products are characterized by high straightness as well as superior impact and compression protection. Our purlin lines are fast and easy to install. They can perform cut-to-length process with a high level of automation.

2. A highly integrated network is used to control this entire machine automatically. This enables a greatly improved performance than previously.

3. This product can act as a kind of building material making machinery. It also functions as colored-coated steel roof forming equipment that is easy to operate, repair, maintain and debug. Additionally, the roll forming dies can be conveniently replaced.

Technical Data of the Cee Purlin Roll Forming Machine

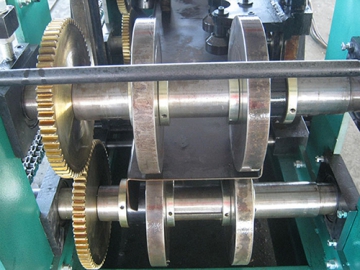

| Shaft | 10-row shaft, Φ90mm, #45 round steel, Tempered solid shaft |

| Thickness of Iron Plate | 20mm |

| Frame | 350mm H steel |

| Roller | Material: bearing steel , Quenched, Tempered hard chrome plating, 10-row forming roll, 2-row pressing roll, 4-row straightening side roll |

| Machine Weight | Approx. 5 tons |

| Overall Dimension | 6200×1000×900mm |

| Electrical Control System | DELTA PLC system for accurate counting |

| Motor Power | 7.5KW, cycloidal speed reducer |

| Power of Hydraulic Cutter | 4kW |

| Production Speed | 8-10m/min |

| Pressure of Hydraulic Power Unit | 18-20Mpa |

| Purlin Specification | 300-500mm |

| Sheeting Thickness | 1.8-4mm |