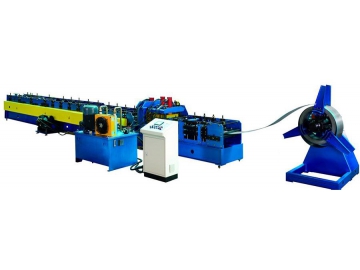

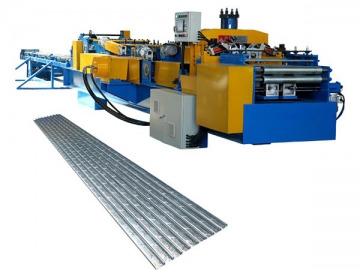

Cee Purlin Roll Forming Machine (Stepless Cutting)

Benefits of the Cee Purlin Roll Forming Machine:

1. Quick Die Change

1) The C purlin roll forming machine allows for quick die change, which helps to dramatically save your production time.

2) It offers a selection of manual mode, semi-automatic mode and fully-automatic model, enabling flexibility for any customer’s needs.

3) The product specifications can be changed at random, thus enabling a more flexible manufacturing process than previously.

2. Extremely High Efficiency

We boast a team of talented employees who devote themselves to the roll form line for greatly increased efficiency.

1) The product specifications are fast changed within 10 minutes to simplify the die change process and thereby help you save much time.

2) Stepless adjustment of specifications can be achieved in optional modes: manual mode, semi-automatic mode and fully-automatic mode.

3) User-friendly purlin forming machine

3. Superior Quality

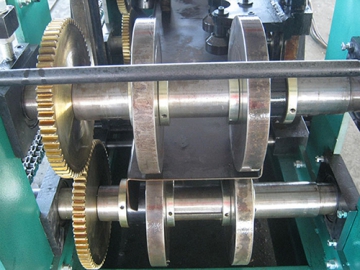

1) This C purlin forming unit features a coaxial design. All the roll-formed plates are uniform in shape.

2) Convenient angle adjustment

3) Easy operation and considerable energy savings

4. Stepless Cutting Technology

1) After roll forming is completed, you can conduct the shearing process without changing any cutting tool. This will also help to save much time.

2) The cutting tools are adjustable at random by using a stepless cutting machine.

Technical Parameters of the Cee Purlin Roll Forming Machine

| Machine Size | 10.0*1.3*1.2m |

| Machine Weight | Approx. 6 tons |

| Sheeting Thickness | 1.5-3mm |

| Forming Shaft | 15 rows (3 rows for leveling, 12 rows for rollforming ) |

| Motor Power | 11kW |

| Shaft Diameter | 80mm (galvanized solid shaft) |

| Roller Material | Bearing steel |

| Frame Material | 350H steel |

| Thickness of Iron Plate | 18mm |

| Drive Method | Sprocket and chain |

| Size of Sprocket and Chain | 1.97 inches |