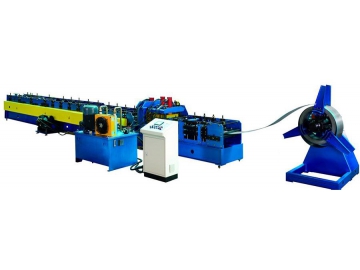

Cee Purlin Roll Forming Machine (Die Cutting)

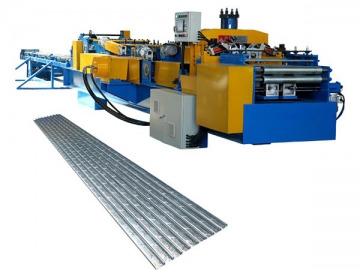

The cee purlin roll forming machine comes with a die cutting unit. It runs steel plates or strips through the cold roll forming process to form a major component of lightweight steel frames, called cold-formed steel. Upon request, our purlin rollforming line can provide cold-formed steel with ultra-low wall thickness. This will greatly simplify the production process and also contribute to a significant increase in production efficiency.Unlike those hot roll forming machines, the cold rollformer is built to produce cold-formed steel materials and a wide variety of profiles that possess uniform wall thickness and complicated cross sections.

Main components of the purlin line include:

1. A passive decoiler,

2. An uncoiler base,

3. A feedstock guiding table,

4. A leveling unit,

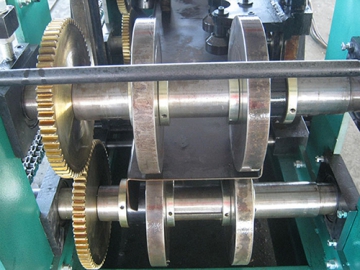

5. A roll forming unit,

6. A punching unit,

7. A cutting unit,

8. A hydraulic power unit

9. And an automatic control system etc.

Technical Parameters of the Cee Purlin Roll Forming Machine

| Overall Dimension | 23000×2400×1400mm |

| Electrical Control System | Variable-frequency PLC control system |

| Motor Power | 11kW |

| Power of Hydraulic Cutter | 15kW |

| Production Speed | Approx. 9m/min. |

| Pressure of Hydraulic Power Unit | 18-20Mpa |

| Purlin Size | 80-300mm |

| Sheeting Thickness | 1.5-3 mm |