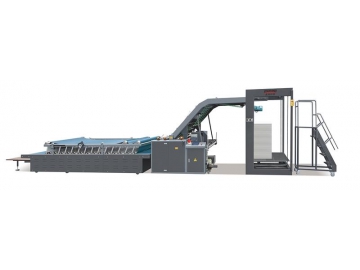

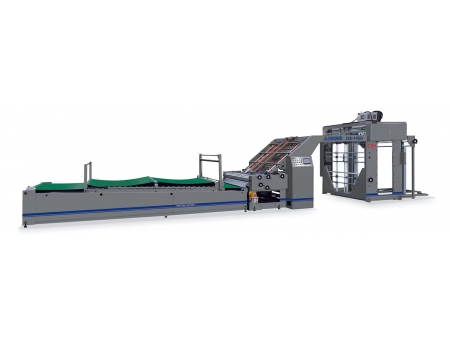

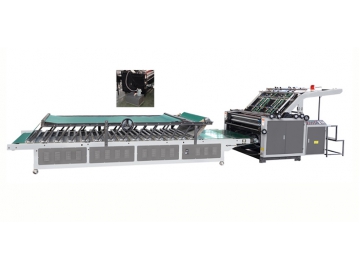

Flute Laminator (Semi-Automatic)

The semi-automatic high speed servo flute laminator machine has three different models for customers to choose from. The maximum range of cardboard this machine can process is 1600 x 1300mm, and the productivity reaches 90m/minute, easily meeting most manufacturing plant capacity requirements.

Features

1.The feeding on the high table, automatic feeding for bottom sheets, and elastic front register all feature a simple operation.

2.Paper feeding requires only one person. Paper quality does not matter, and the machine is suitable for laminating normal paperboard, bottom paperboard, ABCDE Flute corrugated cardboard and filmed paper.

3.The top sheet is manually fed in a forward manner on the high table, and sheets can be piled as high as 1.8 meters.

4.The bottom sheet is automatically fed, and both sheets are piled freely, giving the machine its high efficiency.

5.An advanced elastic front register is used for location and a high register precision, which the bottom paper will never exceed. When laminating, it is easy to align both the top and the bottom sheet, as well as allow the top sheet to exceed the register.

6.The glue supply system is fully automatic, and supplied during the lamination. This avoids wasting glue.

7.The laminating machine features a scientific design with its linear speed in the metering roller, which avoids glue from being thrown around during high speed operation.

8.The machine uses a PLC control system. When compared with other time delay devices or middle relay controls, the bottom paper transference is more precise and stable. The speed has also been increased, and the circuit breakdown can automatically display and alarm users about problematic operations.

9.It is easy to clean the lower roller in the gluing section with a blade and circulating water. The blade completely cleans the roller, and it is easy to replace.

10.The floating movable pressing section is used to make the laminated paperboard smooth. This section can be moved back and forth to easily move the paper as needed.

11.A gear rack is used to control the lift of the water tray, which can easily be removed for cleaning.

Working Principle

The sheet is first transported manually to the front gauge positioning for orientation. A photo electricity switch starts the vertical pump valve after it receives the signal, and allows the bottom sheet to move along the belt. An electromagnetic clutch automatically feeds the bottom sheet from the feeder. The bottom sheet is then oriented at a front positioning together with the front sheet after gluing, and is then moved to another position with a thrust generated by the roller beneath the bottom sheet. The top and bottom sheets are glued together using a lamination roller and a press roller, and are then moved to the pressing area.

| Model | Max Sheet size | Min Sheet Size | Total power | Speed (m/min) | Weight |

| 1300 x 1300mm | 320*450mm | 7kw | 0-90 | 3500kg | |

| 1450 x 1300mm | 320*450mm | 7kw | 0-90 | 4000kg | |

| 1600 x 1300mm | 320*450mm | 7kw | 0-90 | 4500kg |