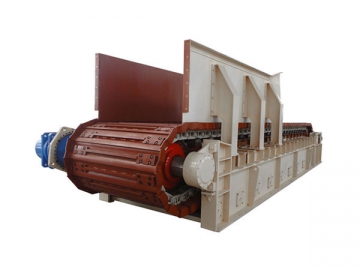

Apron Feeder

Heavy Duty Apron Plate Feeder, Apron Pan Feeder, Apron Feeder for Cement, Apron Feeder for Building Material

Dongmeng heavy duty apron feeder is utilized to transmit and feed materials continuously and evenly for stone crushing machines or other equipment. It is suitable for transporting massive, granular, or powdered materials in cement production lines, and can work normally under harsh environment of high temperature and high moisture. Currently, Dongmeng apron feeder is mainly used in cement plant to feed limestone and raw ore, as well as in metallurgy, coal, chemicals, power, building materials, and machinery manufacturing industries, etc.

Main features of the apron feeder

1. BW series apron feeder is of wide application. Those materials with sharp edged and corners, large granularity or may do harm to the transmission belt are also acceptable. It can transport products with high temperature lower than 400℃.

2. This kind of apron feeder for cement can be arranged flexibly. It can transmit left, right, horizontally, or aslant. The tilt angle is adjustable from 0° to 30°.

3. With high strength of the traction chain, the feeder is competent in long-distance transmission.

4. The plate of the conveyor is of high flexural strength and is resistant to impact

5. Stable running & low noise

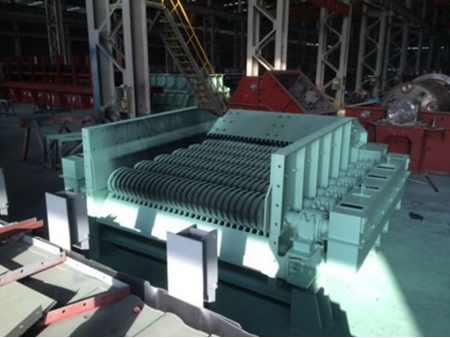

Working principle of the apron feeder

This kind of feeder is comprised of 2 ZG series inertial vibrators, a shock absorber, and a feeding tank. The feeding tank will perform simple harmonic motion along the direction of the composition of forces with the 2 vibrators mounted symmetrically on the tank. The feeding tank will perform reciprocating linear vibration along an inclined direction. When the component force of the vibration acceleration is larger than that of the gravity acceleration, the materials will be thrown into the air and jump ahead along a parabola, and this process will repeat as the tank vibrates another time. In this way, the materials are fed into the crushing plant.

| Model | Width of the slot board (mm) | Central distance between the head and tail shafts (mm) | Feeding granularity (mm) | Processing capacity (t/h) | Power (kw) |

| BW80-L | 800 | 3~15 | ≤350 | 0.2~75 | 2.2 |

| BW100-L | 1000 | 3~18 | ≤600 | 18~18.5 | 5.5~18.5 |

| BW120-L | 1200 | 4~20 | ≤600 | 30~220 | 11~18.5 |

| BW125-L | 1250 | 4~20 | ≤600 | 40~150 | 11 |

| BW140-L | 1400 | 5~20 | ≤900 | 20~200 | 22 |

| BW150-L | 1500 | 5~20 | ≤900 | 40~300 | 22~30 |

| BW160-L | 1600 | 6~20 | ≤900 | 27~300 | 30 |

| BW180-L | 1800 | 6~20 | ≤970 | 30~350 | 22~55 |

| BW200-L | 2000 | 8~20 | ≤1500 | 300~800 | 45 |

| BW220-L | 2200 | 8~20 | ≤1500 | 150~820 | 45 |

| BW230-L | 2300 | 8~20 | ≤1500 | 200~600 | 45 |

| BW240-L | 2400 | 8~20 | ≤1500 | 220~680 | 45 |

| BW250-L | 2500 | 10~20 | ≤1500 | 220~680 | 45 |