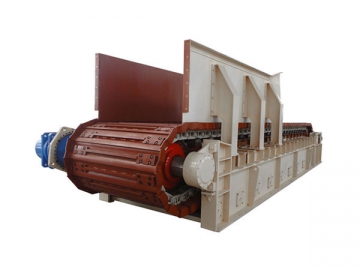

Vibrating Pan Feeder

Vibratory Pan Feeder, Stone Crushing & Screening Line, Vibrating Pan Feeder for Stone, Rock Crushing Line

GZG series vibrating pan feeder is extensively applied in the crushing and screening equipment of metallurgy, coal, mineral processing, artificial sand, construction waste recycling, building materials, and chemical industries. It is designed to transmit the massive, granular, or powdered materials continuously or quantitatively to the processing machineries from warehouses or coppers.

Main features of the vibrating pan feeder

1. It is suitable to deal with all kinds of ores, especially viscous types. The performance of the feeder will not be influenced when it works in dusty or wet environment.

2. Dongmeng vibrating pan feeder employs sealing structure for its body to prevent dust pollution.

3. The vibratory pan feeder uses ZG series inertial vibrator as the vibration source. It is of little consumable parts. During installation, the tank should be inclined at a certain angle (generally 10°-15°) to increase the feeding amount.

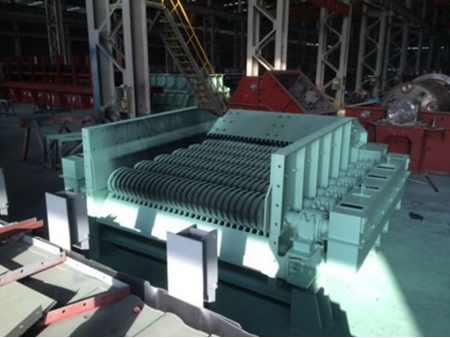

Working principle of the vibrating pan feeder

This kind of vibrating feeder comprises 2 sets of ZG inertial vibrators, shock absorber, and feeding tank. Since the 2 vibrators are mounted symmetrically on the tank, the feeding tank will perform simple harmonic motion along the direction of the composition of forces. The feeding process is realized relying on the reciprocating linear vibration along an inclined direction done by the feeding tank. That is to say, when the component force of the vibration acceleration is larger than that of the gravity acceleration, the materials will be thrown into the air and jump forward along a parabola. So, they will be thrown again when there is another vibration. In this way, the feeding process will be efficiently realized.

| Model | Tank size (mm) | Max feeding granularity (mm) | Processing capacity (t/h) | Power (kw) | Weight (t) | Dimension(mm) |

| GZG8012 | 1200×800 | 200 | 80-160 | 1.2×2 | 0.5 | 2580×1430×600 |

| GZG1014 | 1400×1000 | 300 | 160-300 | 1.5×2 | 0.7 | 3260×1200×850 |