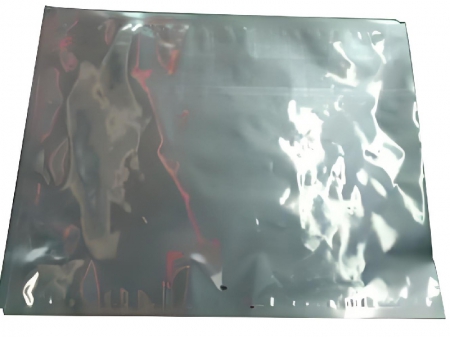

FKSV50B Foil Insulation Facing

Heat-Sealing Foil-Kraft-Scrim Facing, Radiant/Vapor Barrier

Due to its external heat-activated polyethylene coating, the foil insulation facing can be laminated with glass wool and other traditional thermal insulation materials through heating. Requiring no additional adhesive during lamination process, it is environmental friendly and easy to use.

By constructing the fiberglass scrim reinforcement between the external vinyl coating and kraft paper, the foil insulation facing offers better wearing resistance. Also, it is characterized by superior dimensional stability and good resistance to corrosion, water vapor, etc.

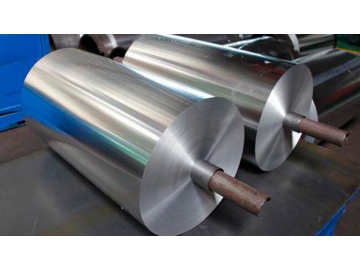

Construction| Composition | Description | Value (Metric) |

| Foil | Aluminum | 7 micron |

| Adhesive | Heat-Resistance Glue | -- |

| Kraft | Natural | 50gsm |

| Reinforcing | Fiberglass Scrim | 12.5x12.5 mm space |

| Heat-Activated Coating | Polyethylene | 25 micron |

| Physical Property | Value (Metric) | Test Method |

| Basic Weight | 100 gsm | Scale |

| Tensile Strength | 135 N/25mm - MD | ASTM D828 |

| 70 N/25mm- XD | ||

| Burst Strength | 35 N/cm2 | ASTM D774 |

| Temperature Resistance | Remains Flexible No Delamination | ASTM C1263 - 29℃/ 66℃ |

| Dimensional Stability | Less than 0.5% | ASTM D1204 @ 150F (65℃) |

| Emissivity | 0.03 | ASTM E408 |

Available Roll Width: 1.20 m

As an experienced FKSV50B foil insulation facing manufacturer and supplier in China, we also provide FGV1808 foil fiberglass facing, MPE100 single sided MPET woven, RAC100A aluminum foil reflective insulation, and reinforced aluminum foil tape, among others.