YX15/25-840/900 Double Layer Roll Forming Machine

Request a Quote

YX15/25-840/900 double layer roll forming machine is capable of producing double layer roof panels. This machine features increased output and saves space, coming with a production speed of 15m/min. The produced wall panel and corrugated sheet is optional in the thickness range of 0.4-0.8mm and an effective cover width of 900mm and 840mm.

Samples

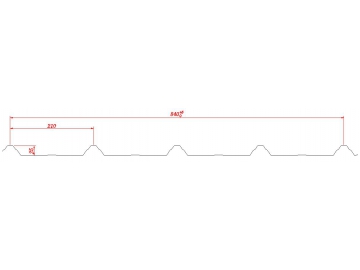

Profiles

| Model | YX15-900/YX25-840 |

| Dimension | 7500*1500*1500mm |

| Motor Power | 7.5KW |

| Hydraulic Power | 2.2KW |

| Forming Steps | 14steps for YX25-840 |

| 9steps for YX15-900 | |

| Forming Speed | 10-15m/min |

| Voltage | 380V/50HZ/3PH |

| Material Thickness | 0.4-0.8mm |

| Rib Height of Roofing | 15mm,25mm |

| Effective Cover Width | 900mm, 840mm |

| Feeding Material Width | 1000mm |

| Control System | PLC Control |

-

Cutter is manufactured by Cr12 mold steel, with HRC58-60 heat treatment for high quality and long service life.

-

Roller is made of high quality 45# steel with CNC lathes.

Hard chrome plating is available for long service life.

Body frame is welded with 400# H bean.

-

PLC control system can be chosen from Schneider, Siemens, and Delta.

-

Hydraulic pre-cutter can be chosen for operation to save labor cost.

- Main Machine

- 5 Tons Manual Uncoiler

- Hydraulic Forming Cutter (Material: Cr12Mov with heat treatment)

- Hydraulic System

- PLC Computer Controlling System with touch Screen (Brand: Schneider)

- Manual Pre-cutter OR Hydraulic Pre-cutter

- Tools

- Operation Manual