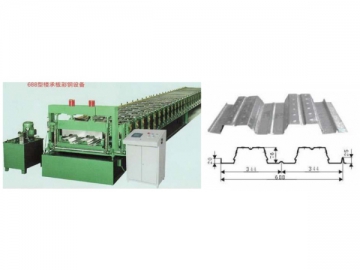

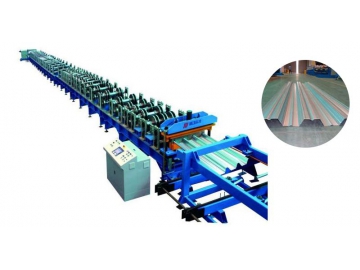

688 Metal Deck Roll Forming Machine

The 688 roll forming machine is used to produce metal decks that possess the features of light weight, high mechanical strength, great loading capacity and superior anti-shock properties. It is widely applicable to multi-storey, high-rise and steel-framed buildings.

Main Features of the 688 Metal Deck Roll Forming Machine

1. This deck forming machine is well adaptable to the fast construction of the main steel structures. It can offer a robust work platform in the shortest possible time. This roll form line allows for the laying of roll-formed decks on multiple floors. It also enables the casting of concrete slabs on separate layers.

2. The metal deck can be used as the steel rebar of the concrete flooring system for greatly increased hardness and considerable material savings.

3. The embossed surface of the roll-formed sheet helps to maximize the binding force between the metal deck and concrete. The use of a stiffening rib adds ultra-high bearing capacity to the entire floor decking system.

4. The metal deck can only function as a permanent template when a cantilever is used. The length of the cantilever depends on the cross section of the metal deck. In order to prevent the cantilever from cracks, a negative-moment reinforcing bar is needed and mounted on the holder.

Technical Parameters of the 688 Metal Deck Roll Forming Machine

| Dimension | 16000mm ×2000mm×1600mm |

| Roll-Forming Shaft | 24 rows |

| Roller Material | 45# steel |

| Thickness of Roller Coating | 0.05mm |

| Cutter Material | Cr12 |

| Forming Speed | 9-10m/min. |

| Electrical Control System | PLC-based industrial control system |

| Motor Power | 15KW |

| Power of Hydraulic Power Unit | 4KW |

| Sheet Thickness | 0.8-1.2mm |

| Width of Expanded Sheet | 1000mm |