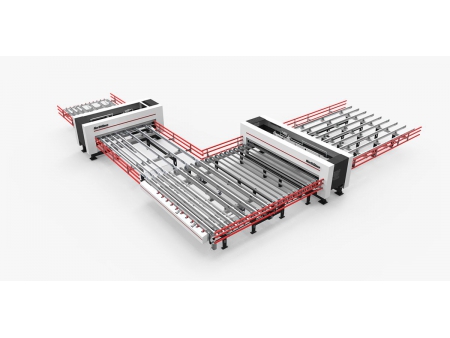

Run-out Measuring Machine

The run-out measuring machine supports axial and radial run-out measuring of wheel rims. To meet the demand for takt time measuring, the clamp mechanism, climbing mechanism and hold-down mechanism all utilize pneumatic actuators to achieve a quick wheel rim clamp and positioning.

The workpiece is transferred to the preset position in this measuring process directly from the previous process. The measuring switch detects the workpiece, and the clamping mechanism conveys it below the measuring station. It is there the climbing mechanism will lift it to a specific point, and clamp it, while the hold down mechanism offers a firm compression. The servo motor then rotates the workpiece to allow for testing with the measuring mechanism. The final, qualified workpiece will then be transferred to the next process, and rejected workpieces are sorted out using the sorting device.

Features- The run-out measuring machine features an automated process and test data visualization.

- This equipment ensures a stable output, enhanced quality, reduced energy consumption, high efficiency and practicality of the entire wheel production cycle.