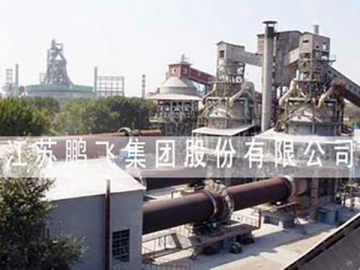

Active Lime Rotary Kiln

Active lime rotary kiln is a device for calcination of active lime. It is made up with barrel, supporting device, supporting device with catch wheels, transmission device, lubrication device and sealing device for kiln tail. Both ends of the rotary kiln are well sealed using combined-type flakes, which helps to reduce the air leakage coefficient to less than 10 percent. To reduce radiation heat loss, composite refractory materials are used to make the lining of the kiln. The kiln features simple structure, high reliability and high degree of automation.

Generally, vertical preheater with reasonable structure and low pressure drop is adopted to increase preheating efficiency. The vertical preheater will enhance the decomposition rate of the lime in the kiln up to 20 to 25 percent. Lime with size ranging from 10 to 15mm can be delivered in the kiln directly without preheating.

Fill-up round or square vertical cooler with zoned ventilation is able to ensure the temperature of lime discharged from the cooler is 80℃ higher than environment temperature, which facilities transportation and storage of the lime. Meanwhile, the exhaust gas, which leaves the cooler and then blows into the kiln, will be heated to over 700℃. In this way, the waste heat is efficiently used, thereby reducing energy consumption.

Technical Parameters| Capacity( t/d ) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | Active Lime and Dolomite | |

| Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Round or Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | |

| Rotary Kiln | Size( m ) | Φ2.5×40 | Φ2.8×42 | Φ3×46 | Φ3.2×50 | Φ3.5×54 | Φ3.6×56 | Φ3.8×58 | Φ4×60/Φ4.2×50 | Φ4.3×58 | Φ4.3×64 | Φ4.8×68 |

| Effective Volume( m³ ) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Buring Temerature( ℃ ) | 1350/1250 | 1350/1250 | 1350/1250 | 1350/1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | |

| Fuel | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | Gas, Coal Powder | |

| Heat Rate( KJ/KgC3O ) | 5300/5000 | 5300/5000 | 5300/5000 | 5300/5000 | 5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |