Active Lime Production Line

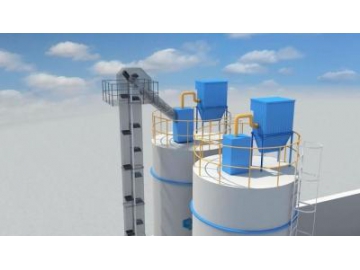

Active lime production line consists of vertical preheater, rotary kiln, vertical cooler, effluent treatment system and coal powder preparation system.

First, limestone is lifted to the storage silo through the chain bucket elevator. Then the electro-vibrating feeder brings the limestone from the silo to the vertical preheater for preheating. The limestone is distributed evenly on the comb board of the heating chamber in the preheater. With temperature of 800℃, the flue gas at the kiln outlet serves as heat source for preheating. After preheating, the temperature of the flue gas drop s to 150 to 250℃ and the gas will be delivered to the bag-house dust collector through pipeline for purification. In this way, no pollution will be created when emitting the gas to the environment. Moreover, reuse of the flue gas reduces energy consumption greatly. Then, the preheated limestone will be pushed to the rotary kiln evenly and continuously.

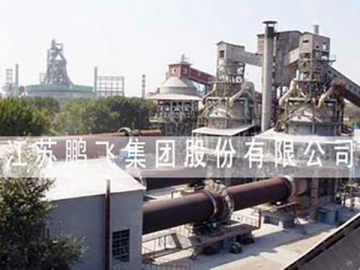

The limestone will enter the preheating zone in the rotary kiln first. The zone can be decreased properly because the limestone is preheated before entering the kiln. Then the ratio between length and diameter of kiln shell is reduced to 14 to 16 from 18 to 23. As a result, smaller installation space and lower transmission power are required. Moreover, heat lost of the kiln surface can be significantly decreased as well. Then the limestone enters the burning zone where the limestone will be burned into lime using the multi-channel coal burner we design. At this time, the temperature of the lime reaches up to about 1,000℃.

Then the lime will be transported to the cooler, which integrates with the kiln hood. Later, the chain bucket elevator will carry the cooled lime to another storage silo. Cold air in the cooler will be heated by the heat from the hot lime. The heated air will blow into the rotary kiln through the sealed kiln hood as the primary air used in the kiln. In this way, the excess heat of the lime can be efficiently used, thus saving energy.

The production line is highly automatic, which enables operators to monitor every procedure such as feeding, burning and product delivering on a PLC or DCS control system.

Technical Parameters| Capacity ( t/d ) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | Active Lime | |

| Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | Polygonal Vertical Preheater | |

| Rotary Kiln | Size (m) | Φ2.5×40 | Φ2.5×40 | Φ3×46 | Φ3.6×40 | Φ3.5×54 | Φ3.6×54 | Φ3.8×58 | Φ4×60 | Φ4.3×58 | Φ4.3×64 | Φ4.8×68 |

| Burning Temperature | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | |

| Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | Square Vertical Cooler | |

| Fuel | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | Gas , Coal Powder | ||

| Heat Rate (KJ/KgCaO) | 5000 | 5000 | 5000 | 5000 | 5225 | 5225 | 5100 | 5100 | 5100 | 5100 | 5100 | |