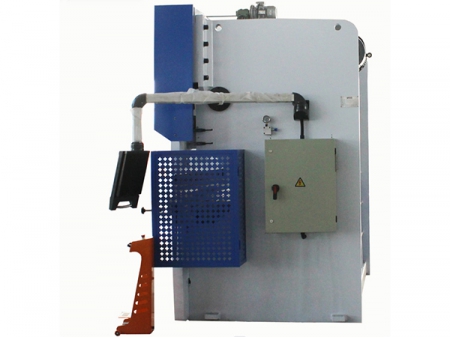

Hydraulic Press Brake

Hydraulic bending machines are classified into upper tool moving and lower tool moving types according to their moving manner. A press brake machine is generally comprised of a bracket, a working table and a clamping plate; wherein the working table consisted of a base and a press plate is arranged on the bracket. The base composed of a base housing, coil and a cover is connected with the clamping plate through hinges, among which the coil is arranged in the recess of base housing. During operation, the coil is energized to generate attractive force upon the press plate so as to clamp the sheet between the press plate and the base. Since the electromagnetic force is used for clamping, the press plate can process various kinds of workpieces including those possessing side walls. By changing the dies for bending, the sheet metal bending machine can process various kinds of workpieces.

Our hydraulic swing beam shear is one of the most preferred options for sheet metal forming, thanks to its advanced technology and dependable performance. Its application has expanded across various sectors, including aerospace, shipbuilding, railways, electrical engineering, mining, construction machinery, metallurgy, automotive, and agricultural machinery, driven by continual improvements in process technology.

| Model | Nominal pressure | Worktable length | Distance between columns | Throat depth | Stroke | Opening | Motor | Dimensions |

| ton | mm | mm | mm | mm | mm | kW | mm | |

| | 40 | 1600 | 1280 | 250 | 120 | 325 | 4 | 1850×1300×2100 |

| | 40 | 2000 | 1550 | 250 | 120 | 325 | 4 | 2250×1300×2100 |

| | 40 | 2500 | 2050 | 250 | 120 | 325 | 4 | 2750×1300×2100 |

| | 63 | 2500 | 2050 | 250 | 120 | 360 | 5.5 | 2750×1350×2230 |

| | 63 | 3200 | 2600 | 250 | 120 | 360 | 5.5 | 3450×1350×2230 |

| | 80 | 2500 | 2050 | 320 | 120 | 380 | 7.5 | 2750×1400×2350 |

| | 80 | 3200 | 2600 | 320 | 120 | 380 | 7.5 | 3450×1400×2350 |

| | 100 | 2500 | 2050 | 320 | 120 | 380 | 7.5 | 2750×1450×2380 |

| | 100 | 3200 | 2600 | 320 | 120 | 380 | 7.5 | 3450×1450×2380 |

| | 100 | 4000 | 3200 | 320 | 120 | 380 | 7.5 | 4250×1450×2380 |

| | 125 | 2500 | 2050 | 320 | 120 | 380 | 7.5 | 2750×1450×2380 |

| | 125 | 3200 | 2600 | 320 | 120 | 380 | 7.5 | 3750×1450×2380 |

| | 125 | 4000 | 3200 | 320 | 120 | 380 | 7.5 | 4250×1450×2380 |

| | 160 | 3200 | 2600 | 320 | 180 | 450 | 11 | 3450×1700×2600 |

| | 160 | 4000 | 3200 | 320 | 180 | 450 | 11 | 4250×1700×2600 |

| | 200 | 3200 | 2600 | 320 | 200 | 470 | 15 | 3450×1850×2860 |

| | 200 | 4000 | 3200 | 320 | 200 | 470 | 15 | 4250×1870×2950 |

| | 250 | 3200 | 2600 | 400 | 250 | 530 | 18.5 | 3450×1920×3050 |

| | 250 | 4000 | 3200 | 400 | 250 | 530 | 18.5 | 4250×1950×3150 |

| | 300 | 3200 | 2600 | 400 | 250 | 560 | 22 | 3450×2200×3130 |

| | 300 | 4000 | 3200 | 400 | 250 | 560 | 22 | 4250×2250×3320 |

| | 300 | 6000 | 4700 | 400 | 250 | 560 | 22 | 6100×2250×4250 |

| | 400 | 3200 | 3200 | 400 | 300 | 640 | 30 | 3200×2280×3250 |

| | 400 | 4000 | 3200 | 400 | 300 | 640 | 30 | 4000×2300×3600 |

| | 400 | 6000 | 4700 | 400 | 300 | 640 | 30 | 6000×2350×4650 |

| | 500 | 4000 | 3200 | 500 | 310 | 640 | 37 | 4000×2480×4330 |

| | 500 | 6000 | 4700 | 400 | 310 | 640 | 37 | 6000×2450×4700 |

| | 600 | 6000 | 4700 | 460 | 310 | 650 | 45 | 6000×2700×5710 |

- The hydraulic swing beam shear is built with a welded steel frame that eliminates vibration and stress, ensuring high durability and rigidity.

- Equipped with E21 control system for precise control over slide and back gauge movement, enabling efficient and accurate positioning.

- The hydraulic shear includes an upper die compensation mechanism that adjusts for flex during bending, guaranteeing high precision in the final product.

- Economical upper die clamps offer fine adjustments through wedges, making the metal shearing machine versatile for various tasks.

- The molds can be customized according to specific bending requirements, enhancing the swing beam shear’s adaptability to different projects.

- An integrated hydraulic system with top-tier components and seals from renowned companies reduces piping and ensures reliability and safety during operation.

- Safety is prioritized with emergency stop buttons installed on the E21 controller and foot pedal, protecting users during operation.

- Mechanical stops inside the cylinders ensure repeatable slide positioning accuracy, crucial for maintaining consistent bending angles in batch production.

- Sunny pump for optimal performance

- Servo drive for precise control

- High precision back gauge system

- Mechanical clamping system for press brake tooling to enhance safety during mold changes

- Portable wireless foot pedal for press brake operation

- Safety guard for operator protection

- Larger opening height, throat depth, and distance between columns, coupled with an extended slide stroke, accommodate bending and handling of large, complex workpieces

- Controlled by the ESTUN E21NC system for efficient operation

- Integrated hydraulic control system for streamlined and efficient operation

- Incorporates a mechanical crowning device, serving as a deflection compensation mechanism to ensure precision

- Safety light curtain

- Quick tool changer

- Safety light curtain

- Manual compensation system

- Front support arm