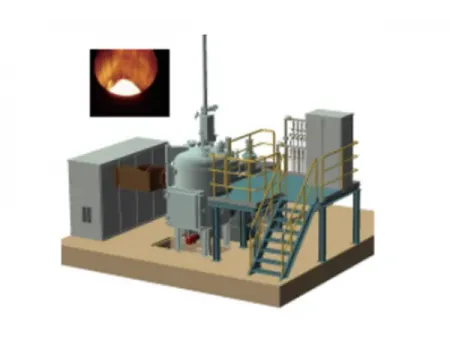

Water Cooled Copper Crucible Suspension Smelting Furnace

Vacuum Metallurgical Equipment

Our water cooled copper crucible suspension smelting furnace is an advanced vacuum refining system integrating high-temperature alloy melting, bottom pouring/tilting casting, and precision casting. The furnace utilizes a segmented water-cooled copper crucible as the base, where an intense electromagnetic field induced by the coil enables the metal to be melted in a semi-suspended or fully suspended state.

This technology ensures the high-purity smelting of high melting-point metals while eliminating contamination risks associated with traditional ceramic crucibles. It is ideal for processing active metals, high-purity materials, refractory alloys, semiconductor materials, and radioactive materials, ensuring a uniform metal structure and exceptional purity.

| Crucible capacity | |||||

| Furnace structure | Horizontal | Horizontal | Vertical | Vertical | Vertical |

| Pouring method | Tilt pouring | Tilt pouring | Tilt pouring | Tilt pouring | Tilt pouring |

| Max. temperature (℃) | ≥2800 | ≥2800 | ≥2800 | ≥2500 | ≥2500 |

| Ultimate vacuum level (Pa) | ≤6×1×10⁻³ | ≤6×1×10⁻³ | ≤6×1×10⁻³ | ≤6×1×10⁻³ | ≤6×1×10⁻³ |

| Pressure rise rate (Pa/min) | ≤2 | ≤2 | ≤1.5 | ≤1.5 | ≤1.5 |

| Heating power (kW) | 200 | 250 | 300 | 400 | 450 |

| Temperature measurement method | Thermocouple infrared temperature measurement | ||||

| Other functions | Secondary material feeding | Secondary material feeding,centrifugal casting,mold insulation | |||

- The strong suspension capability of the furnace allows for semi-suspended or fully suspended melting, ensuring optimal purity and uniformity of the metal materials.

- The furnace supports high melting temperatures, making it suitable for high-melting-point materials while maintaining consistent temperature control throughout the process.

- The water-cooled copper crucible design significantly extends the lifespan of the crucible, ensuring greater durability and longevity during high-temperature operations.

- The system accommodates a wide range of specifications, providing flexibility to process various material types and production volumes efficiently.

- The furnace ensures a contamination-free process by eliminating the risk of ceramic crucible contamination, ensuring high-purity results for sensitive and high-value materials.