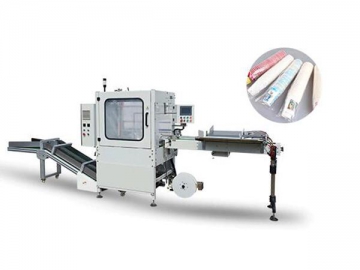

Combing Machine

Combing machine is used in the fiber spinning line between drawing frame and flyer frame to comb out the shorter fibers, remove some debris, increase the effective fiber length, and improve the yarn quality. Since a lot of short fibers will be filtered out in the combing process, combing machine has a direct link with the consumption of raw materials and the production cost.

Salient Features

1. High Performance

BHFA1299A combing machine is a modified model of 1299. It has absorbed the core technique of Rieter, reduced the crank length and the swinging angle of nipper, as well as improved the stability of the whole system. The reduction on crank length has narrowed the change range of combing space and improved the combing effect.

2. Automatic Control

The combing machine is employed with advanced PLC control. With photoelectric or pneumatic sensor, the system is guaranteed with high reliability.

3. Patented

BHFA1299A has obtained several patents, such as automatic stop device (patent No. ZL20092045708.8). The stop device is able to adjust each head of the combing machine individually to meet the required supporting force, ensuring the reliability of the system.

4. Time Saving

Baocheng has developed comb coupling (patent No.: ZL201120050865.0) for the combing process. With the coupling, operators don't have to adjust the location of comb when the length of fibers change, saving a lot of time and labor cost.

5. High Efficiency

BHFA1299A combing machine features little vibration, low noise, and reliable performance. With the working speed controlled at 350 /min, the content of short fiber in the filtered fibers is no less than 70%, and in the fine ones it is no more than 8%. The impurity removal rate of combing machine is ≥50%.

| Head (working station) | 8 |

| Volume of fed fibers | 50~80g/m3 |

| Max diameter of fibers | φ 650mm |

| Fiber width | 300mm |

| Fiber length range | 25~51mm |

| Fiber output | 3~6ktex |

| Speed | 350 /min |

| Rate of falling | 6~25% |

| Length of fed cotton | 4.3, 4.7, 5.2, 5.9mm |

| Circular comb | 90° |

| Separation and pressurization | |

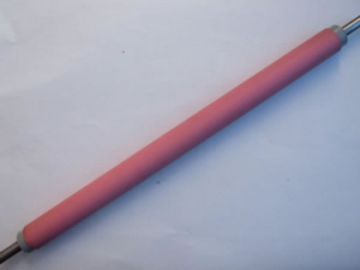

| Separation roller | biconical; with oblique groove |

| Diameter of separation roller | φ 25 |

| Pressurization style | pneumatically |

| Effective fiber length | 26.48mm |

| Fiber output | |

| Output roller | type: oblique groove; diameter: φ 25 |

| Diameter of output roller | φ 45 |

| Diameter of roller of work station | φ 50 |

| Specification of discharge port | φ 5; φ 5.25; φ 5.5; φ 6 |

| Drafting system | pneumatically; 3 over 5; curve drafting |

| Number of fibers | 8 |

| Range of draft multiple | 9~19.3 |

| drafting distance | 41.5~60 |

| Coiler | double can, single coiler |

| Eccentricity | 95mm |

| Can size (diameter × height) | φ 600mm × 1200mm (including roller) |

| Cotton suction | concentrated |

| Compressed air | pressure (MPa): 0.6~0.8; air consumption: (m3/h. set) 0.8; quality level: grade 3; moisture: melting point 2℃; oil content: no more than 1.8mg/m3; pollution: ≤5mg/m3; ≤5μ |

| Cotton suction system | gas volume: 0.85 m3/s U-shaped 25mm water column (static state) |

| Power | main motor (inverter motor): 5.5kw; 50Hz; brush motor: 1.1kw, 50Hz; transformer: 0.4kw |

| Dimension (L×W×H) | 7180 × 2120 × 1790 (mm) |

| Weight | about 4800kg |