Combing Preparation Machine

Baocheng has developed this complex comprised of draw frame and lap former as a preparation for fiber combing process. The design intention of combing preparation machine is to produce a narrow lap from a number of slivers. When it works, it lets the slivers pass through the drafting rollers to straighten and draft them into cotton web. Then the lap winders will wind and roll the web onto a spool to create laps.

BHFA36 draw frame and lap former combination is used before a combing machine in fiber spinning line. It processes 18-28 slivers into cotton webs, and then draft and wind two cotton webs into cotton roll whose diameter is 650mm.

Salient Features

1. The min distance between draft rollers is up to 4 mm, widening the applicable spinning range of fibers.

2. The unique stop device stops the draft roller automatically when the required length has been finished or when there is any failure, improving the equipment's reliability.

3. It is easy to be repaired and maintained.

4. With universal coupling for drafting, the machine's service life has been largely improved.

5. Operations of coiling, feeding, and transporting are accomplished fully automatically.

6. The lamp forming machine is of compact structure, stable transmission, and low energy consumption.

| Applicable fibers | cotton; with a length of 25~51mm |

| Fed slivers Number of lap Feed can Cotton web output | 3.3 ~ 6g/m 18~28 600 × 1200mm 50~80g /m |

| Drafting system | drafting manner: 3 over 3; head: 2; multiple of back drafting region: 1.032 1.062 1.112; multiple of main drafting region: 1.06~2.792; total drafting multiple: 1.094~3.10; distance between draft rollers: 36~50mm |

| Load | loaded pneumatically; 600~800N for each rubber roller |

| Fiber weight Lap width Lap diameter | 25kg (max) 300mm 650mm (max) 80~150m /min (theoretically) 80~120m /min (actually) |

| Space | Length: 8008mm; width: 5876mm; height: 2850mm | |

| Power | main motor/invertor motor: 11Kw; fiber separator: 2.2Kw; isolation transformer: 0.4Kw | |

| Power | 3 × 380V ≤ ± 70% 50HZ | |

| Suction region | local negative pressure: -800Pa (80mm water column) | |

| Gas source | supply pressure: 0.7~0.8MPa; working pressure: 0.6MPa; gas consumption: 2.2~2.3m3/h; main gas pipe: φ 12 × 1 | |

| quality of compressed air ISO8573-1 class 3 | impurity particle density : 5mg/m3; impurity particle size (max): 5μm; oil content of fed air (max): 1mg/m3; max dew point: -20 ℃ | |

| Item | Manufacturer |

| Program controller (PLC) | Delta |

| Contactor | Tianshui 213 |

| Frequency converter | Delta |

| LCD touch screen | Delta |

| Pneumatic component | Camozzi |

| Bearings | NKI (Japan), SKF (Sweden) |

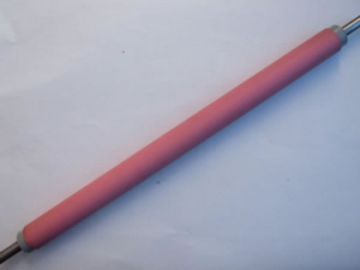

| Rubber roller | BAOHUA |

| Motor | Weinan Heli |

| Photoelectric sensor | RTP |

| Two technical manuals; a mechanical drawing; 64 fabric roll; 4 trolleys | |