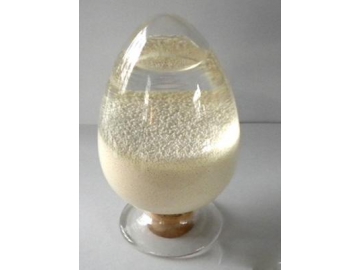

C5 Hydrogenated Petroleum Resin

ALX™-H100 hydrogenation resin is a process used after a resin is polymerized in order to decrease its color and improve the stability with heat, oxygen, and ultraviolet light. The hydrogenation process increases the cost of a resin, due to the improvement of its properties.

Recommended Field

bookbinding, building construction, caulk and sealants, contact adhesive, hot melt adhesives, packaging

Application Function

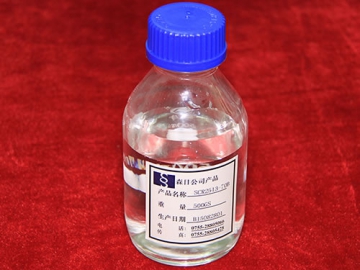

1. Excellent oxidative stability

2. Great compatibility with solvents

Packaging

25kg/bag, kraft paper bag or paper/plastic bag. This can also be customized according to customer requirements.

Delivery time

Generally 10 days, though for large orders and special circumstances we will notify customers in advance if the delivery period will be longer.

Shelf Life and Storage

The hydrocarbon resin belongs to the non-dangerous goods category. During transport, it should not be exposed to sun and rain. The C5 hydrocarbon resin should also not be moved together with spontaneously consumable materials, strong oxidants or strong acids. When storing this resin, keep the storage area ventilated, cool and dry. The storage period is usually a year, however, if the hydrocarbon resin passes inspection after the 1 year period, it can still be used.

| ITEM | Softening Point(°C) | Color G# | TDS |

| 96-104 | Max1.0 |