Double Spindle CNC Drilling Machine

Features and Uses

1. This is a double spindle CNC drilling machine. Two spindles with different speeds enable the drill press to carry out drilling and reaming, or rough reaming and fine reaming, etc. It is widely applied in industries including anchorage device, flange, valve and more.

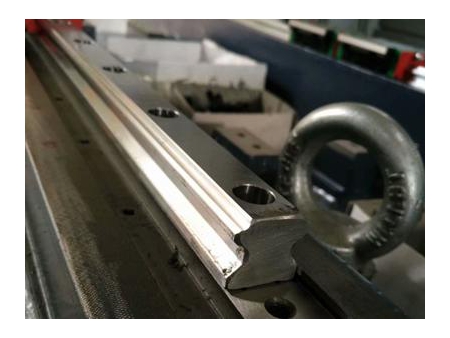

2. The vertical drilling machine features a reinforced type double spindle structure which ensures a high spindle precision, with high rigidity at axial and radial directions.

3. Two spindles are relatively fitted with different tools. To be specific, the spindle I is firstly used to complete rough machining; then, the workpiece is automatically positioned under the spindle II for fine machining. Rough and fine machining is completed at one stroke without having to changing tools.

4. In addition, the CNC drilling machine can also be used to drill two workpieces simultaneously, thus greatly reducing non-cutting time and improving working efficiency.

5. Based on customer's needs, the CNC drill can be equipped with pneumatic or hydraulic chuck, and by means of external hydraulic pump to control the tightening and loosening of workpieces.

Models and Specifications

| Items | Unit | |

| Max. drilling capacity (on the steel with 500~600mpa tensile strength) | mm | 40 |

| Max. feed force | KN | 16 |

| Max. permissible torque of spindle | Nm | 350 |

| Spindle motor power | KW | 4 (Variable frequency motor) |

| Spindle taper | Morse 4 | |

| Spindle nose-to-guideway distance | mm | 335 |

| Spindle travel | mm | 250 |

| Spindle box travel (manual) | mm | 470 |

| Center distance of two spindles | mm | 220 |

| Spindle speed range | r/min | 70-125 150-350 450-800 900-1400 |

| Word feed speed (X, Y, Z axes) | mm/ min | 0.6-3000(X, Y) 0.3-2000 (Z) |

| Rapid feed speed (X, Y, Z axes) | mm/ min | 8000(X, Y) 4000 (Z) |

| Work table size | mm | 850 x 450 |

| Work table area | mm | 710 x 350 |

| Work table travel (X x Y) | mm | 700 x 400 |

| T-Slots width | mm | 18 |

| Max. spindle nose-to-table surface distance | mm | 650 |

| Cooling pump power | KW | 0.09 |

| Positioning accuracy | mm | 0.05 |

| Repeated positioning accuracy | mm | 0.02 |

| Items | Unit | |

| Max. drilling capacity (on the steel with 500~600mpa tensile strength) | mm | 40 |

| Max. feed force | KN | 16 |

| Max. permissible torque of spindle | Nm | 350 |

| Spindle motor power | KW | 4 (Variable frequency motor) |

| Spindle taper | Morse 4 | |

| Spindle nose-to-guideway distance | mm | 335 |

| Spindle travel | mm | 250 |

| Spindle box travel (manual) | mm | 470 |

| Center distance of two spindles | mm | 220 |

| Spindle speed range | r/min | 70-125 150-350 450-800 900-1400 |

| Word feed speed (X, Y, Z axes) | mm/ min | 0.6-3000(X, Y) 0.3-2000(Z) |

| Rapid feed speed (X, Y, Z axes) | mm/ min | 8000(X, Y) 4000(Z) |

| Work table size | mm | 1100 x 450 |

| Work table area | mm | 960 x 350 |

| Work table travel (X x Y) | mm | 850 x 400 |

| T-Slots width | mm | 18 |

| Max. spindle nose-to-table surface distance | mm | 650 |

| Cooling pump power | KW | 0.09 |

| Positioning accuracy | mm | 0.05 |

| Repeated positioning accuracy | mm | 0.02 |