Petroleum Machinery Castings

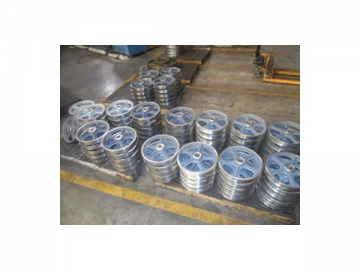

Iron castings used in the petroleum industry need to have a complex structure, high performance, abrasive resistance, high air impermeability, outstanding quality and a high reliability. In our production process, cast iron is first melted using a medium frequency furnace. The liquid cast iron obtained is then poured into a resin sand mold and left to solidify. Once it has solidified, the semi-finished product is cleaned to remove any sand attached and coated in a rust preventative oil. The finished product is then packed in an air tight box.

- pipe fitting

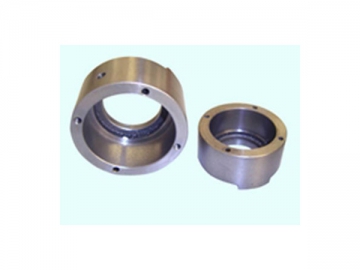

- shell

- end cap

We are able to supply a wide array of high quality and high performance nodular iron castings and gray iron castings to customers in the petroleum industry, and a large number of these castings are exported to Europe and America.

In addition, our iron castings can also be used on electric devices. Raw materials used to make this kind of iron casting has to be carefully selected and the product size must be strictly controlled. A clay sand molding machine is required for the production of castings with a high precision and a complex structure. Here at Hebei Kingdo, we can easily supply iron castings on a large scale.