High Gradient Magnetic Filter

Why choose the High Gradient Magnetic Filter

Customer's issue-The hidden danger of Iron oxide scale

- Bursted Pipes

Rusted Pipes

Rusted Pipes Pipe Maintenance

Pipe Maintenance Bursted Pipes

Bursted Pipes Sediment on the steamer vane

Sediment on the steamer vane

Iron content is higher in the condensation water because of corrosion of the thermal equipment and pipeline in the electric power, steel, petrochemical industries and the like.. When the iron contamination is more than 30mg/cm2 on the furnace tube, it may cause severe problems. If the thickness of sediment on the steamer vane is more than 0.076mm, the working efficiency will decrease by more than 4%. When the iron content is more than thousand of Mg/L in the water, the water can't be recycled to thermal system any longer. This results in a huge amount of water and heat energy being wasted.

The Good News-The High Gradient Magnetic Filter is the fixes the issue of oxide scaling.

The High Gradient Magnetic Filter is a newly developed product by LONGi Magnet based on years of research and incorporating advantages of similar products. It can help avoid accidental bursts caused by the corrosion of pipes, promotes the recovery and reuse of condensation water,and decreases the thickness of iron oxide scaling, as well as decreasing the sediment on the steamer vane.

Application- It is widely applied in the condensation water system of electric power industry , nuclear power plant industry and other steam producing industries. The High Gradient Magnetic Filter can control the magnetic impurity content in the condensation water as the pre- cleaning device.

Protection-Takes away a substantial part of the danger of the high speed mixed bed and the powder resin filter being contaminated with impurities. It can almost double the service life of furnace pickling, the regenerating period of high-speed mixed bed, and the resin film of Powdered resin pre-coat filter .

Energy conservation-Used by power plants that need to rebuild the thermal supply system of large generating sets, the newly built power plant with supercritical 350MW cogeneration units and with power plants having issues recycling the condensation water in the thermal network. The High Gradient Magnetic Filter has the ability to be very adptable, can be used to handle the water with iron content lower than

1000μg/l, and running under 180℃. It also helps to shorten the start time.

Maintenance Free -Free of daily maintenance costs and the user can expect lower power consumption.

Application

1.Widely used for the recycling of condensation water, drain water, and steam-condensed water of power plants. It is a necessary device for frequently peak regulation power plant.

2.It is a necessary device to remove tramp iron in thermal network of reconstructed power plant

3.It is a necessary device for the fluidized bed boiler.

4.For the water filter system of the petrochemical industries, steel plants, silicon industries, paper mills, and even industries such as the tobacco industry

5.Works as a pre-filter of the ion-exchanger to improve the water quality, relieve resin being oxided , and extends the lifetime of resin. To purify the high temperature water, emulsion, degreasing fluid in the metallurgical industries, especially the sheet processing.

Features

Maintenance Free——no need to change filters

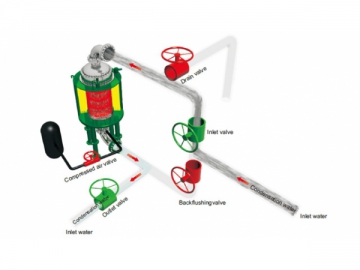

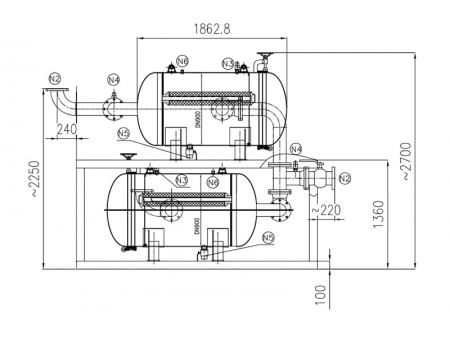

I. The core of The High Gradient Magnetic Filter is made by special stainless steel. It is corrosion resistant and wear-resistant. The High Gradient Magnetic Filter employs impulsing steam-water with combination back flushing. The configuration of the filter cores are from sparse to dense making it well suited for back flushing. The life time of the filter core can be more than 10 years.

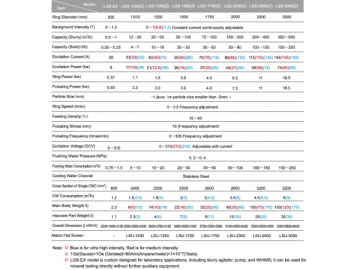

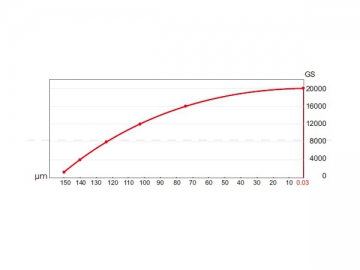

II. High efficiency——apply to high-temperature 180℃;available to remove 0.03μm~150 μm iron oxide.

The Filter core is made of a highly magnetic gathering soft magnetic steel, suitable for 180℃ condensation water. The external magnetic field and the wall of container are equipped with thermal-protective coating, which isolate the internal heat conduction well.

The cooling system is a combination of forced oil cooling and water cooling.

The filter core is made of high magnetic gathering stainless steel, 20000Gs magnetic intensity and 1000Gs/μm. The magnetic gradient is generated under the external magnetic field. The configuration of the filter cores are from sparse to dense, in order to absorb all of the 150 μm ~0.03μm magnetic suspended solid and colloid while water flows through the filter. Removal rate of magnetic objects in the water is above 99.5%, and iron content in outlet water is lower than 5mg/L.

III. Energy conservation——low operation cost

The only operation cost of high gradient magnetic filter is the power consumption. Decreasing the excitation while higher water quality is available can help to decrease the power cost.

IV. Low investment——Less pumps invested

The operation pressure difference is only 0.02Mpa~0.03Mpa so there is no need to add any pumps for existing projects.

V. Convenient operation——With a touch screen control panel and a computer interaction link control is available both on site and remotely.

Working principle sketch

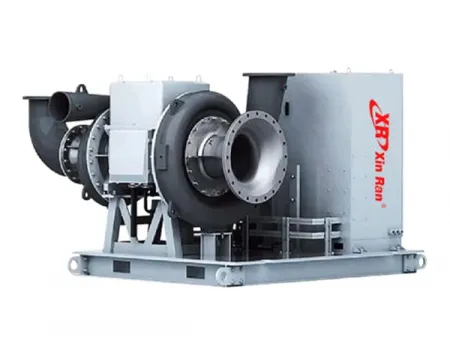

Longi Magnet Company has focused on manufacturing mining magnet separation equipment, magnet flotation and filtration equipment and solutions for customers since 1993. As a leading high gradient magnetic filter manufacturer, we make effort to provide quality magnetic impurity removal machine and solution in customer needs.