Magnetic Flotation Separator

Introduction

The development of the LJC automatic magnetic flotation separator was caused by a breakthrough based on research of dewatering tanks, magnetic flocculations, magnetic columns, wash mills and the like. This innovation allows for a large capacity unit capable of greatly increasing the concentrate grade automatically in a reliable environment while also saving on water and power.

It set the national standard for the 5th generation of magnetic gravity separation equipment.

Won The 2013 National Important New Product Award and The Provincial Science and Technology Progress Award.

Was awarded 6 national patents, including:

-Full-automatic Flotation Separator ZL2011 2041 4368.4

-Full-automatic Control System ZL20112029 6729.X

-Forward and Reverse Magnetic Field ZL2011 2015 1578.3

-Appearance and Design of Full-automatic Flotation Separator ZL2012 3001 6764.1

-Adjustment Device of Overflow Level ZL2011 2019 0904.7

-Cable Connection Device of Full-automatic Flotation Separator ZL2012 2015 3682.6

Applications

The magnetic flotation separator is generally utilized in the finishing separation stage. It was designed for use with ferromagnetic minerals having a susceptibility higher than 3000x 10-6 cm/g and has been found to normally increase the concentrate grade by 2-9% which can greatly increase the systems overall efficiency.

The magnetic flotation separator has been proven to be an excellent choice for a wide variety of ferrous minerals.

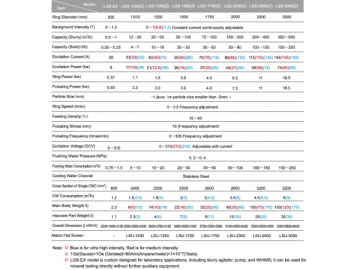

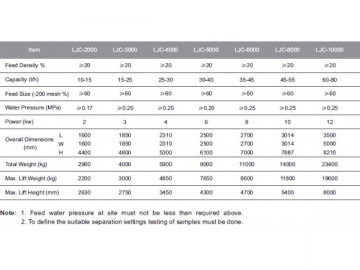

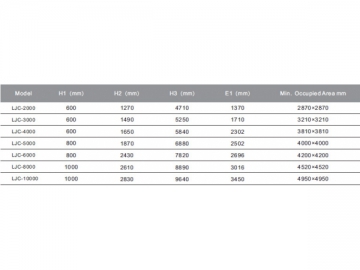

Technical Parameters

Features

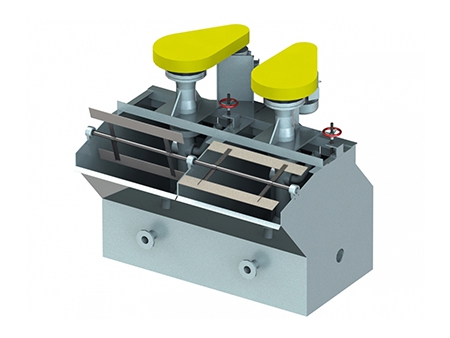

1.A Large Increase in The Concentrate Grade. A positive and negative pulsation of the magnetic field allows for the particle to be loosely suspended in a slurry for a thorough discharge of the gangue and intergrowth. This enables the separator to both effectively improve the grade of the magnetic concentrate and control the magnetic material from draining into the tailings.

2.A High Degree of Automation. The water and slurry volume, overflow density, discharge density and magnetic intensity is all automatically adjusted based on the specific properties of the minerals. This virtually guarantees the best separation possible throughout the process, even when the material's properties change through normal fluctuations of ore grade.

3.Simplified Process Flow. The magnetic flotation separator replaces the traditional finishing equipment. By doing so it not only lessons the amount of equipment needed to complete the process, but, also reduces both water and power consumption.

4.Stable Separation. By means of having a larger separation area the amount of fluctuations in the end product are greatly reduced. When the change of material is within 60% of the normal feed product the end user can expect a stable and consistent product.

5.Power and Water Savings. Positive and negative pulsations of the magnetic field, automatic feed control over the water and slurry levels as well as the magnetic intensity all allow for the maximization of resource use.

6.Remotely Controlled. Using a PLC module the unit can easily be monitored and adjusted, if ever desired, from the end users computer system in the central control room.

7.Adaptable Capacity. Based on the customer's needs, there are models ranging from the LJC-2000 to LJC-9000. This allows the end user to select a device capable of processing for their needs, up to 80 tons per hour per unit.

Structure

Installation Requirement

Incline angle of feed pipe must be larger than 12°

Horizontal change of the overflow surface must be within ±2mm

Feed water pressure must not be less than the value listed in the Technical Parameters.

Work Sites

Since 1993, Longi Magnet Company has over 20 years of experience in the manufacture of industrial and mining magnet separation equipment and machine. As a leading magnetic flotation separator manufacturer, there are different models of flotation separation machines for choose. With over two decades of experience, we make effort to provide quality magnet flotation separation equipment and efficient solutions for customers.