The automatic welding line is used for the production of mesh baskets & drawers. Designed for precision forming and welding, this mesh basket welding system seamlessly integrates five key processes: wire mesh forming, side strip forming, welding for combination, mesh basket forming, and edging.

Experience optimal efficiency with an estimated daily production ranging from 450 to 500 pieces over an 8-hour shift, depending on proficiency levels.

Mesh Basket & Drawer Welding Line

- 1. Flattening and cutting of bottom mesh—bottom mesh forming

- 2. Flattening and cutting of side mesh—shearing of trapezoidal side mesh—side mesh forming—side mesh edging

- 1. Side strip of bottom mesh: straightening, rolling, and cutting—bending—welding

- 2. Handle side strip: straightening, rolling, and cutting—bending

-

Wire mesh making machine

Wire mesh making machineThe wire mesh making process involves wire mesh stamping, rolling, straightening and shearing.

Thickness of steel sheet: 0.2-1mm Stamping speed: 280 times/min Stamping width: ≤600mm -

Wire mesh shear cutting & bending machine (for mesh basket side forming)

Wire mesh shear cutting & bending machine (for mesh basket side forming)The square wire mesh is stamped and sheared into trapezoidal shape.

-

Bottom mesh deep drawing press

Bottom mesh deep drawing pressThe square mesh is stamped and pressed into a U-shaped bottom mesh.

-

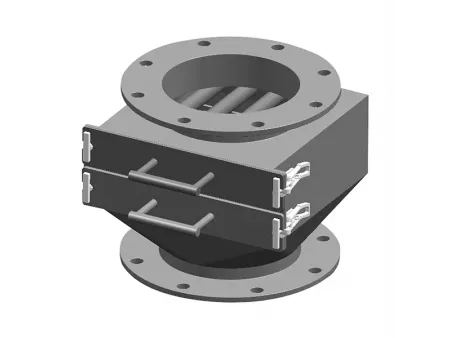

Spot welder (for side and bottom welding)

Spot welder (for side and bottom welding)Secure the bottom mesh and side mesh combinations using a spot welder.

-

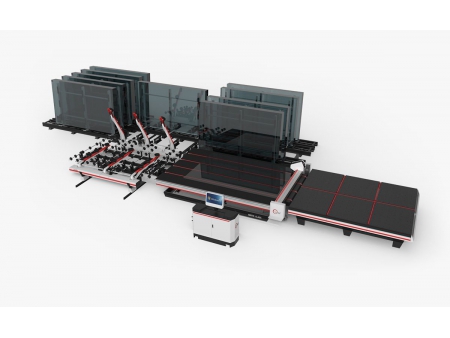

Multi-head mesh welding machine

Multi-head mesh welding machineAfter manual loading and unloading, assembly of side and bottom mesh will be performed by the multi-head mesh welding machine.

-

Steel edge trim straightening & cutting machine

Steel edge trim straightening & cutting machineUtilize the roller press to shape the steel strip into a V-shaped edge strip. Input the desired length, and the equipment will automatically straighten and cut the strip to the specified length.

- Steel edge trim bending machine

Use the bending machine to bend the side strips into the shape of the frame with smooth and flat surface.

- Steel edge trim butt welding machine

Two ends of the steel strips are joined by the butt welding machine. The joint is strong and durable.

- Steel handle edge trim bending machine

The steel strip is bent into U-shaped handle by the bending machine. Two steel handles can be bent at a time.

- Handle edging machine

The hydraulic edging machine is used to secure the handle edge strips to the bottom mesh opening.

- Mesh basket edging machine

The mesh basket edging machine is used to assemble the side strips with the bottom mesh.

If you have any business inquiries or product questions, please feel free to contact us.